What is reflection haze?

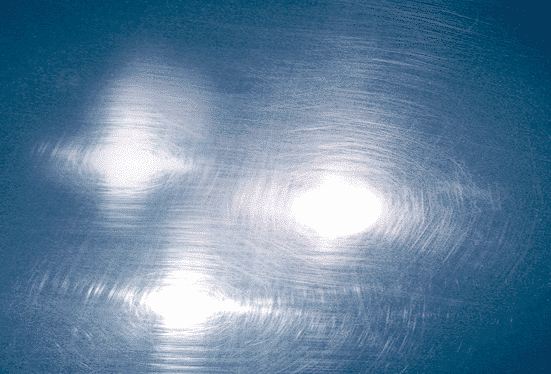

A surface with a highly reflective finish can be seen to have a deep reflection and a high reflective contrast. However, one that exhibits a slight “milky” finish, observed as a milky halo or bloom from a reflection on the surface, is said to be suffering from Haze; the word Haze, therefore, is used to describe this effect.

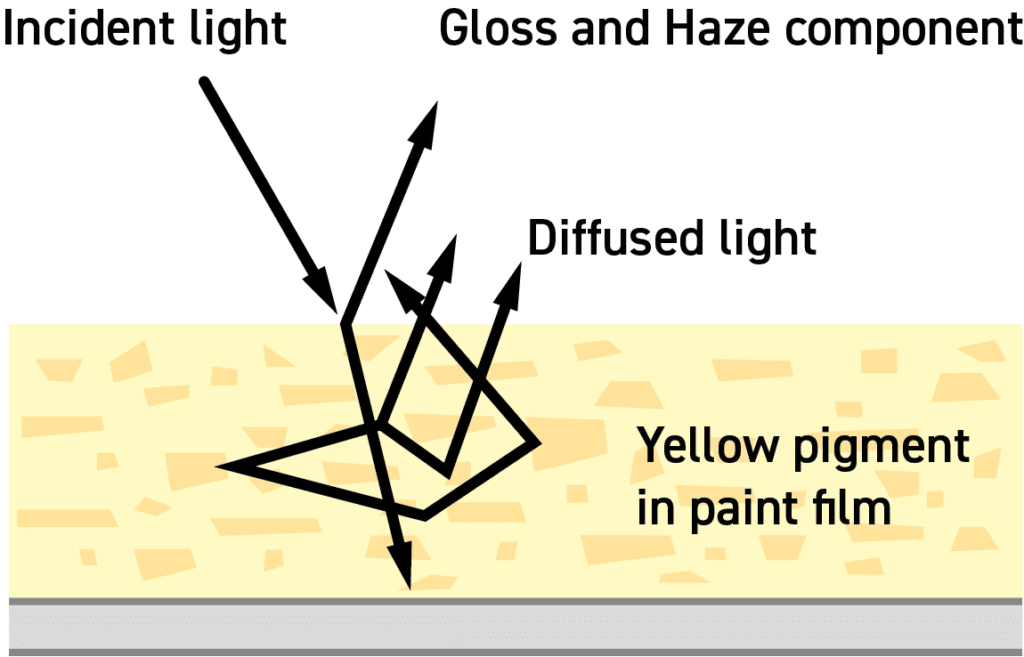

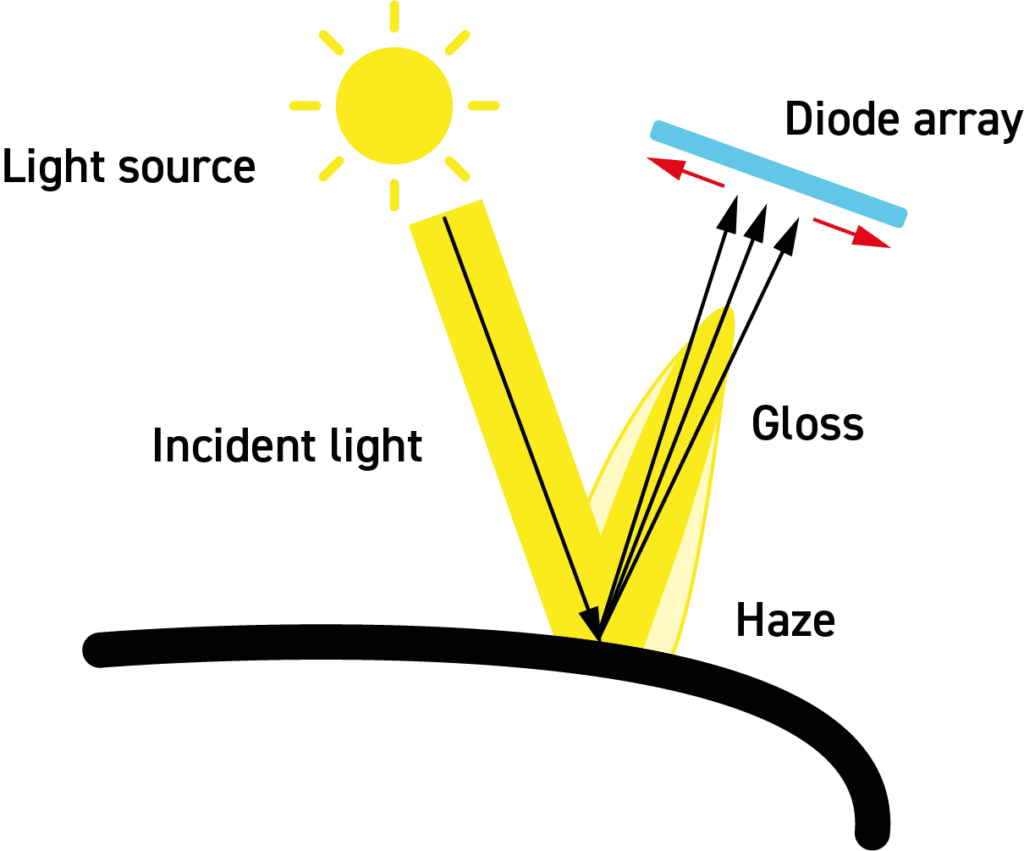

Haze is caused by microscopic surface textures that diffuse light adjacent to the main specular component of reflected light. When viewing the reflection of a strong light source in a surface with high haze the image “blooms” and has a bright halo around it.

Surface haze can be problematic in many coatings applications including automotive manufacture, powder coatings and other high gloss coatings. It can be attributed to a number of causes including incompatible materials in a formulation, poor dispersion and problems encountered during drying/curing/stoving. Haze is an important measure for highly polished metals and is often associated with polishing marks and machining direction.