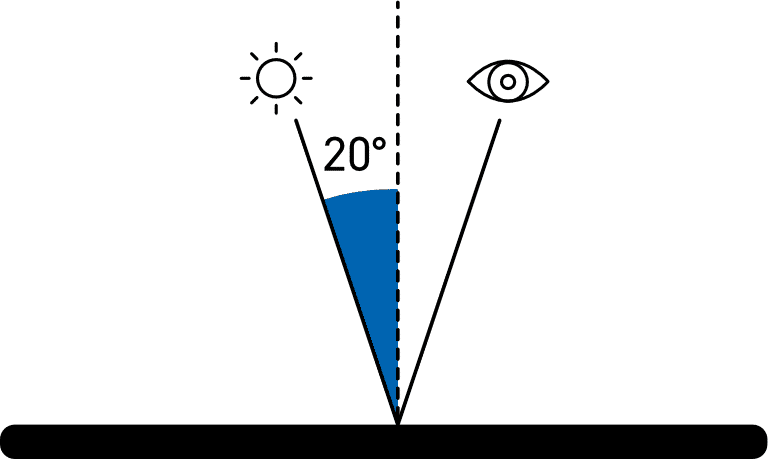

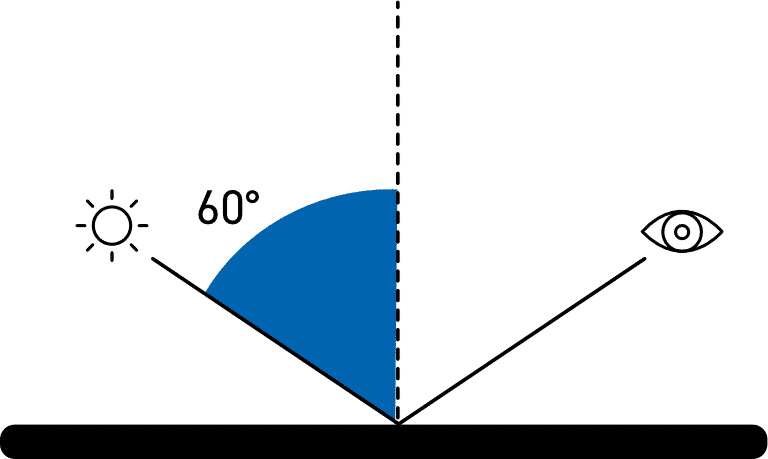

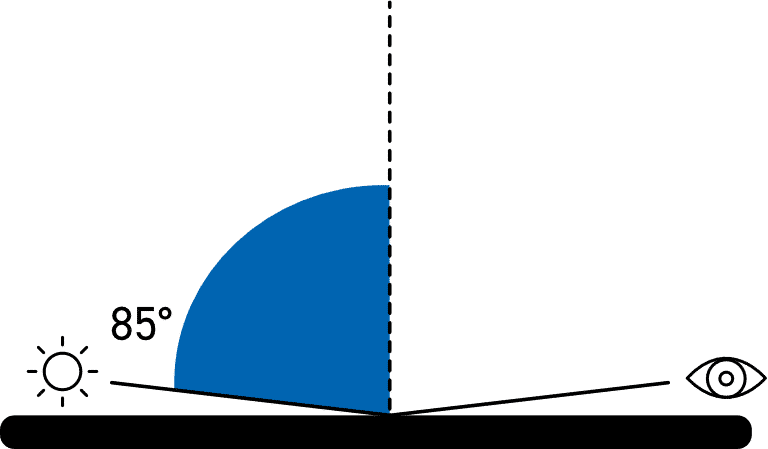

Many industries have adopted the 20/60/85º geometries as specified in ISO2813/ ASTM D523, however consult the table below for more information on specific industries and their industrial standards.

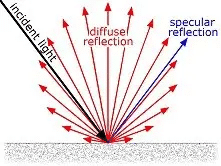

General Gloss measurement

ASTM D523 1999 (USA)

Test method for specular gloss

The principal ASTM specular gloss standard. Very similar to ISO 2813

ASTM D3928 1998 (USA)

Test method for evaluation of gloss or sheen uniformity

ASTM D4039 1999 (USA)

Test method for reflection haze of high-gloss surfaces

ASTM D4449 1999 (USA)

Test method for visual evaluation of gloss differences between surfaces of similar appearance

ASTM D5767 1999 (USA)

Test methods for instrumental measurement of distinctness of image gloss of coating surfaces

ASTM E430 1997 (USA)

Test methods for measurement of gloss of high-gloss surfaces by goniophotometry

MFT 30-064 (South Africa)

Local version of ASTM D523

JIS Z8741 1997 (JAPAN)

Method of measurement for Specular glossiness

Paint

IS0 2813 1994 (International)

Paints and varnishes – determination of specular gloss of non-metallic paint films at 20°, 60° and 85°

The principal ISO specular gloss standard. Very similar to ASTM D523

The following are technically similar to ISO 2813:

BS 3900: Part D5 1995 (UK)

Methods of test for paints – optical tests on paint films – measurement of specular gloss of non-metallic paint films at 20°, 60° and 85°

DIN 67530 1982 (Germany)

Reflectometer as a means for assessing the specular gloss of smooth painted and plastic surfaces

NFT 30-064 1999 (France)

Paints – measurement of specular gloss

at 20, 60 and 85°.

AS 1580 MTD 602.2 1996 (Australia)

Paints and related materials, methods of test – introduction and list of methods.

JIS Z8741 1997 (Japan)

Specular glossiness – Method of measurement.

SS 18 41 84 1982 (Sweden)

Paints and varnishes – measurement of specular gloss of non-metallic paint films at 20, 60 & 85°

Plastics

BS 2782: Pt 5, Method 520A 1992

Methods of testing plastics – optical and colour properties, weathering – determination of specular gloss

Similar to ISO 2813

ASTM D2457 1990

Test Method for Specular Gloss of Plastic Films and Solid Plastics

Specifies the primary standard as a perfect mirror with a defined gloss value of 1000. 20°, 60° and 45°; the 45° method is as ASTM C346 for ceramics.

Metals

BS6161: Part 12 1987

Methods of test for anodic oxidation coatings on aluminium and its alloys – measurement of specular reflectance and specular gloss at angles of 20°, 45°, 60° or 85°

Ref. Std BS 3900: Part D5 (1980); technically equivalent to ISO 7668 replaces BS 1615:1972. At 45°, dimensions of source image and receptor aperture are as for 60°. Squares with sides equal to the shorter sides of the rectangles are also recommended. Alternatively, total reflection in a 45° prism is used as a reference; source image and receptor aperture are then circular, both with angular diameter 3.44° ± 0.23° (1.5 mm ± 0.1 mm at 25.4 mm focal length)

IS0 7668 1986

Anodized aluminium and aluminium alloys – measurement of specular reflectance and specular gloss at angles of 20°, 45°, 60° or 85°.

IS0 5190

Anodizing of aluminium and its alloys – evaluation of uniformity of appearance of architectural anodic finishes – determination of diffuse reflectance and specular gloss

ECCA T2 (European Coil Coating Association)

Specular gloss at 60°.

Paper

DIN 54502 1992

Testing of paper and board; reflectometer as means for gloss Assessment of paper and board

ASTM D1223 1998

Test method for specular gloss of paper and paperboard at 75°.

Has unusual converging beam geometry. Specifies the primary standard as black glass of refractive index 1.540, not 1.567, at the sodium D-line having a defined gloss value of 100.

ASTM D1834 1995

Test method for 20° specular gloss of waxed paper

Another unusual converging beam geometry, different to the previous one.

TAPPI T480 OM-90 1990 (USA)

Specular gloss of paper and paperboard at 75°

Same text as ASTM D 1223

TAPPI 653 1990

Specular gloss of waxed paper and paperboard at 20°

Probably the same text as ASTM D 1834

JIS – Z8142 1993 (Japan)

Testing method for 75° specular gloss

Furniture

BS 3962: Part 1 1980

Methods of test for finishes for wooden furniture – assessment of low angle glare by measurement of specular gloss at 85°

Similar to ISO 2813: 1978

Floor Polish

ASTM D1455 1987

Test method for 60° specular gloss of emulsion floor polish

Ref. std ASTM D 523

Ceramics

ASTM C346 1987

Test method for 45° specular gloss of ceramic materials

Ref. std ASTM D 523

ASTM C584 1981

Test method for 60° specular gloss of glazed ceramic whitewares and related products

Ref. std ASTM D 523 {Sheen}

Fabrics

BS 3424: Method 31: Part 28 1993

Testing coated fabrics – determination of specular gloss