Durability and Abrasion Testing

A laboratory Rub Proof Tester is a tool for comparing the rubbing, scuffing and marking of inks and coatings on commercial print and packaging, it can be used as part of quality control in a production environment or as an aid to development in the laboratory.

Protective packaging, magazines, labels and promotional material are all printed with inks and coatings which are designed to remain clear, bright and undamaged during the items lifetime.

Unfortunately movement during packing, shipping or everyday handling can cause items to mark or scuff. The coatings and substrates used, the cure conditions and the amount of abrasion all affect the severity of this damage.

Modern papers and carton boards can prove a challenge for inks and coatings, harsh substrates such as matt paper and recycled board are prone to marking, scuffing and rubbing during post-print production and transportation.

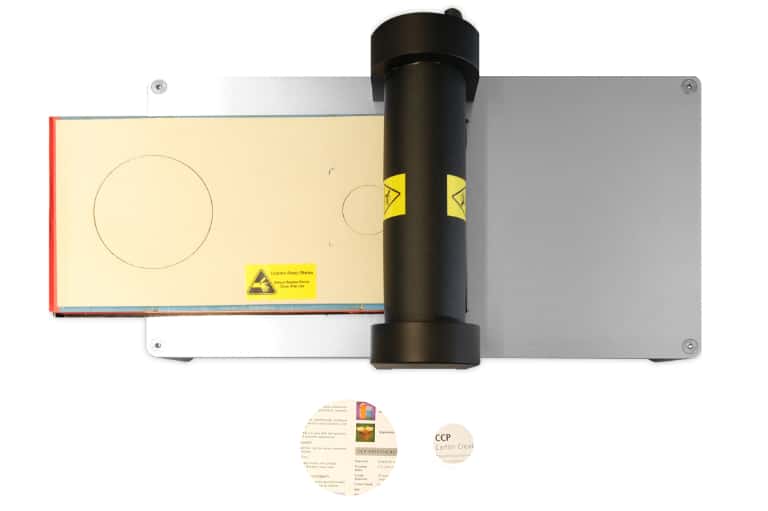

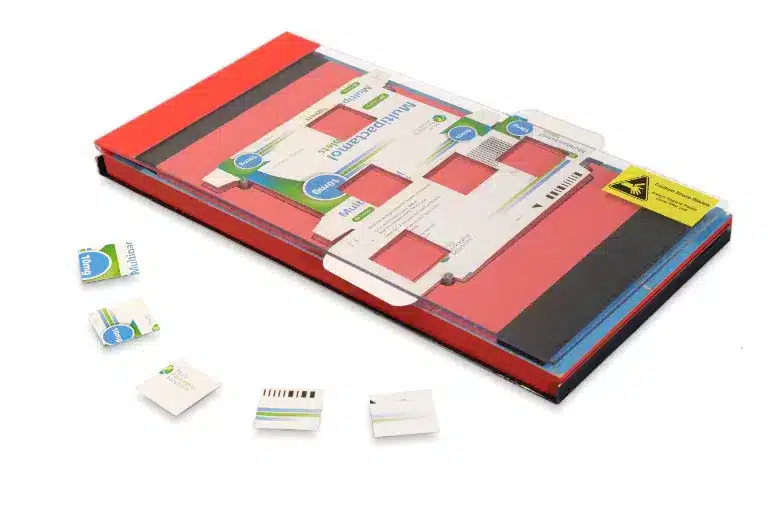

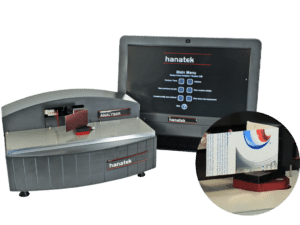

The Hanatek ink rub tester allows the user to compare the durability of printed cartons, commercial print or proofs of ink and varnish on a wide range of substrates.

The instrument uses a rotary motion to abrade the printed surface against a smaller sample of the same printed surface or a reference white material. To mimic the effects seen in a production environment, the test can be performed as a ‘face to reverse’ also. The user can vary the abrasion force and the number of cycles to adjust the severity of the test. More information on test procedures can be found in BS3110.

The Hanatek rub tester replicates the test method used on older style instruments such as the Pira Wallace rubproofness tester but benefits from the inclusion of digital weight and cycle selection, assuring accurate unsupervised abrasion testing.