Appearance & Measurement Experts since 1986

Fully characterise all aspects of appearance perception.

Advanced and complete analysis of transparent appearance.

Ideal for gloss measurements of all surfaces and is suitable for matt to mirror gloss surfaces.

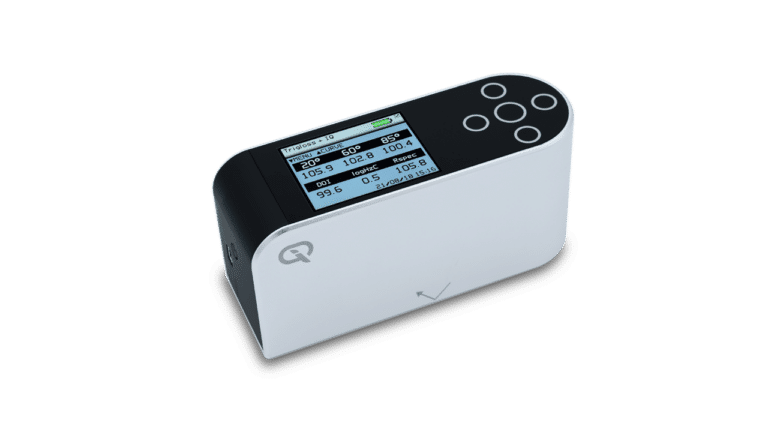

The Rhopoint IQ Gloss, Haze & DOI Meter quantifies surface quality problems that are invisible to a standard glossmeter and profiles how light is reflected from a surface.

We offer local support in many countries. Contact your local agent for advice and information about our instruments.

Ensure your instrument is giving accurate results by sending off for calibration via one of our global accreditation centres.

Rhopoint Instruments Ltd is certified to ISO 9001:2015 for Quality Assurance and is a member of the British Coatings Federation (BCF).

Selecting the correct angle for the application will optimise measurement accuracy. Three types of instruments are available on the market: 60° single angle instruments, a

The diagram above shows the same coating applied to two panels, the first has orange peel/waviness present due to the incorrect application setting on the

Rhopoint offer a variety of products for testing gloss, haze and DOI.

For measuring gloss of flat surfaces; our Novo-Gloss gloss meter range is an ideal choice. We offer a range of products for testing all finish levels from matt to mirror. All Novo-Gloss glossmeters are supplied with a calibration tile; both this and the instrument have calibration certificates included in the price. The gloss meter instruments themselves are incredibly easy to use whilst offering advanced features such as software-free data transfer, graphing of statistics, batching and pass/fail.

For high gloss surfaces that exhibit other texture effects, our Rhopoint IQ instrument measures not only gloss but also reflectance haze (the ‘milkiness’ of a surface) but DOI (distinctness of image) and RIQ (reflected image quality) DOI and RIQ are measures of orange peel within a painted or high gloss finish.

In this range, our flagship product is the MFFT (Minimum Film Forming Temperature) instrument. Trusted by the leading coatings manufacturers, the Rhopoint MFFT can be found in the R&D labs of most of these companies worldwide. The Rhopoint MFFT is used to determine the minimum film forming temperature and white point in paint and coatings such as water based coatings, polymer dispersions, synthetic latexes and emulsion.

We also offer viscosity flow cups – Afnor, BS, ISO, ASTM/Ford, DIN and Frikmar flow cups in all orifice sizes with certificates of conformity.

Rhopoint offer a range of test instruments for measuring flexible packaging. The products are designed to provide manufacturers and users of flexible packaging material with consistently faster packaging speeds with the same batch to batch quality.

Produced under the brand name of Hanatek, our instruments are designed to be used in both research and development and production environments in numerous industries including: plastic film, carton board, paper, corrugated board, textile, inks and coatings, labels etc.

Parameters measured include friction, thickness, board stiffness, crease recovery and film shrink.

Our Optimap and TAMS products characterise common surface irregularities including defects, waviness and roughness

The Rhopoint TAMS™ can measure and map surfaces at all stages of paint processes from raw material to final topcoat. Map and measure surface quality

With the Optimap PSD, quantify faults such as orange peel, waviness and DOI. Results are displayed in industry compatible units ( K, Ka, Kb, Kc, Kd, Ke )

The Rhopoint ID characterises the transparency of a material in a single measurement. Measured parameters are haze, transmission haze (ASTM D1003 correlaton) clarity and sharpness – a new parameter which matches human perception. One of the key features of the Rhopoint ID is that it can measure curved samples and small sample sizes that cannot be measured with a traditional haze meter which means the product is ideal for use not just for the measurement of sheeted plastic film but also products such as PET bottles, visors and glass.