Measurement Pressure

Many materials including plastic film, plastics, and rubber may crush or deform dependent on the pressure applied during testing and the momentum of the presser foot.

Textiles require high pressures during testing to remove wrinkles and airgaps.

Tissue thickness testing demands a light measurement pressure and slow presser foot speed so the paper fibres are measured without being crushed and flattened.

Tissue thickness testing demands a light measurement pressure and slow presser foot speed so the paper fibres are measured without being crushed and flattened.

It is clear that different industries have adopted measurement parameters that give meaningful results for their own application.

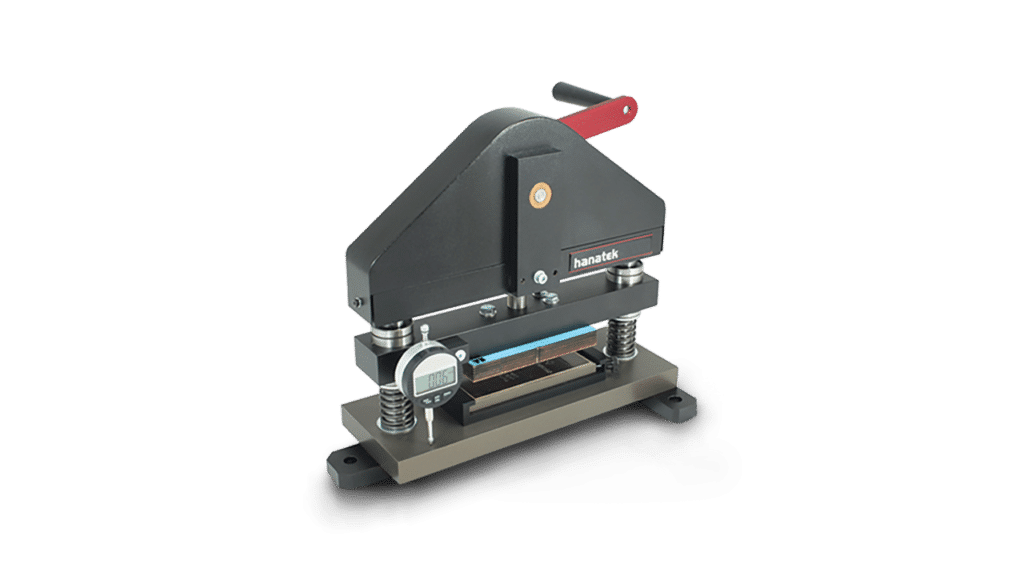

FT3 measurement forces are applied using fixed masses; each instrument is supplied ready to apply the exact force specified in the relevant international standard.

The FT3-V variable pressure thickness gauge can be useful if a sample needs to be tested to more than one standard, it can also be used to determine the compressibility of samples under different conditions.

The measurement head size and profile is usually determined by the ISO Standard for the material.

- Domed measurement head- Small areas can be measured with high resolution- Plastic films and coatings.

- Small diameter flat measurement heads- used to apply a large pressure in a small area- Paper and board applications.

- A large diameter flat foot – Measures the average thickness of fibrous material over a large area with light pressure – Tissue Paper. Opacity of inks, coatings, plastic film and paper.

Measurement velocity

The speed of the measurement head can also have an effect on thickness measurement. A fast-moving head will impact a sample with more energy and may deform or dent the material.

The measurement velocity of the FT3 head can be set by the user from 1 to 5mm/sec. This speed is sometimes specified in international standards.

The most significant source of measurement error in any system is often introduced by the human operator.

The FT3 family of instruments have a number of features that reduce the impact of a human operator.

Fully automated operation

the main parameters are fully controlled by the instrument; measurement pressure, speed and dwell time.

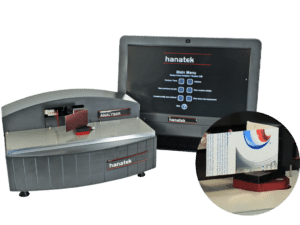

Onboard statistical calculation

Mistakes are often made in transcribing results and calculating statistics, these functions are performed automatically by the instrument.

Results can also be output via RS232 to SPC programs, lab networks or MS Excel.

QA labels record results throughout the batch

Securely time and date stamped labels with statistical results can be produced throughout a batch run and attached to job cards or retained samples. This traceable control gives the customer confidence that the whole batch of product is within specification and allows manufacturers to issue certificates of conformance.