Why measure gloss?

Gloss is an aspect of the visual perception of objects that is as important as colour when considering the psychological impact of products on a

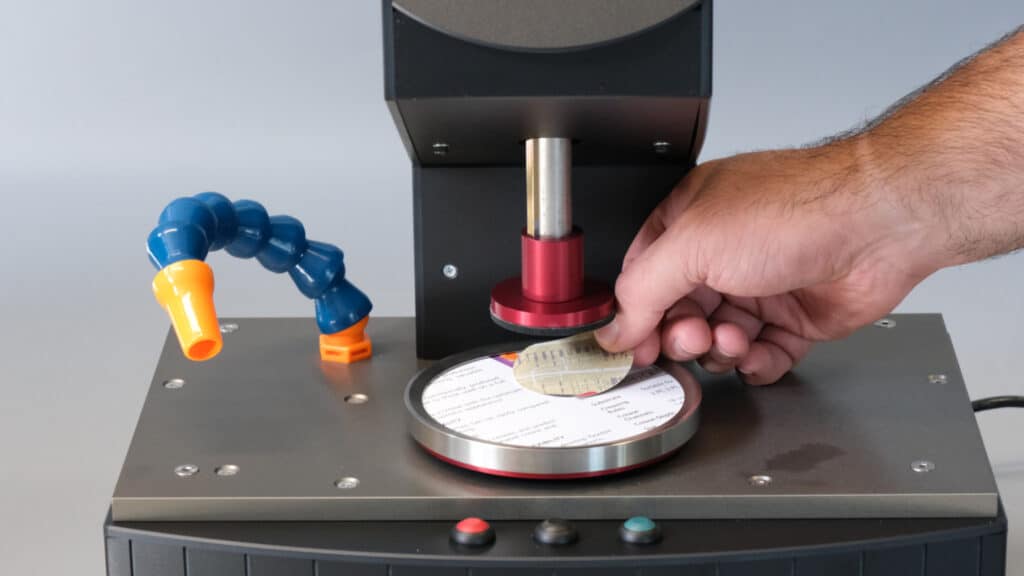

Designed by Hanatek to increase the efficiency and repeatability of rub proof testing, this comparative test works by abrading a printed sample against a reference material under known conditions.

The results can be used to identify alternative substrates, better ink and coating formulations for the suitability of finished cartons, films, printed books, magazines and promotional materials.

The Hanatek Rub & Abrasion Tester can be programmed for the required number of cycles, enabling it to be run concurrently with other laboratory tests.

Optional test attachments offer the ability to conduct tests under harsher conditions and can be used to check the solvent resistance or the cure of UV inks.

A laboratory rub proof tester is a tool for comparing the rubbing, scuffing and marking of inks and coatings on commercial print and packaging. It can be used as part of quality control in a production environment or an aid to development in the laboratory.

Protective packaging, magazines, commercial documents and promotional material are all printed with inks and coatings which are designed to remain clear, bright and undamaged during the items lifetime.

Unfortunately movement during packing, shipping or everyday handling can cause items to mark or scuff. The coatings and substrates used, the cure conditions and the amount of abrasion all effect the severity of this damage.

Touch screen operation ensures quick configuration of test parameters

User-configurable cycle times allow tests be to run unsupervised

Air feed hose to remove fibres and debris which act as abrasive agents

Additional attachments available for abrasion and wet rub tests

Choice of weights to comply with BS3110 methods for measuring rub resistance of print

The instrument platen and test head are driven at an identical speed of 1 rev/sec. This creates a very even abrasion between the top surface and the entire area of the larger test sample.

An air hose blows away sample test debris to ensure no additional abrasion from loose ink particles affects the results.

After testing, the 2 samples are visually analysed. Pass/fail of each test is determined visually or by further analysis by using a densitometer, glossmeter or spectrophotometer.

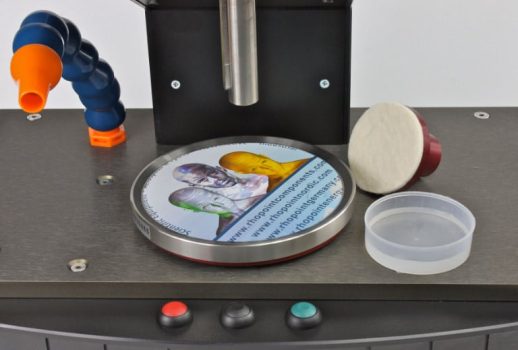

Scratch Pad - used for a more aggressive test useful for assessing through cure of UV coatings or high abrasion transit testing. Available as an optional extra.

Felt Pad - used to test the water, detergent, solvent or fat resistance of inks and coatings. Available as an optional extra.

After every test, the abrasive or felt pad should be checked for damage or excessive coating build up and replaced if necessary.

The standard foam pads should both be inspected prior to testing. Damaged pads can lead to uneven pressure distribution across the sample, resulting in incorrect results.

Simple reporting of results using the results printer can be attached to retained samples

Wet head attachment plus pads

Scratch head attachment plus pads

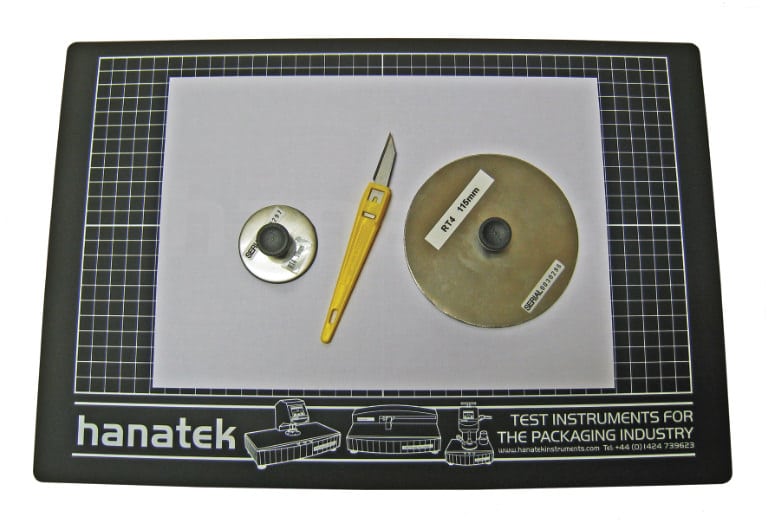

The Universal Sample Cutter allows for faster and safer simultaneous cutting of 50mm and 115mm ø samples. Suitable for all types of sample thickness and medium to high volume testing.

| Specification | ||

|---|---|---|

| Standards | BS 3110 | |

| Weights | 0.5, 1.0 and 2.0 psi pressure | |

| Certification | UKAS traceable calibration certificates (Instrument and test masses) | |

| Power | 110/240V 50/60Hz | |

| Net Weight | 10kg (max) | |

| Dimensions | (H) 420mm x (W) 350mm x (D) 240mm | |

| Packed Weight | 16kg | |

| Packed Dimensions | (H) 500mm x (W) 435mm x (D) 410mm | |

| Commodity Code | 9024 8011 | |

| Order Codes | ||

|---|---|---|

| Rub & Abrasion Tester | HAN-A1002RUBTESTER | |

| Sample Cutter | RL-A80-005 | |

| Wet Test Attachment | HAN-B1002RT4HEAD-W | |

| Scratch Test Attachment | HAN-B1002RT4HEAD-S | |

| UK Printer | HAN-B-PRINTER240 | |

Free extended 2 year warranty: Requires registration at www.rhopointinstruments.com/help-services/forms-feedback/instrument-registration/ within 28 days of purchase. Without registration, 1 year standard warranty applies.

Fast and economic service via our global network of accredited calibration and service centres. Please visit www.rhopointinstruments.com/help-services/calibration-servicing/ for detailed information.

Gloss is an aspect of the visual perception of objects that is as important as colour when considering the psychological impact of products on a

Identify the surface that you wish to measure. Is it a flat surface? If so, it can be measured with a traditonal glossmeter. Curved surfaces

RSpec is the peak reflectance measured over a very narrow angular band in the specular direction (+/-) 0.0991º. RSpec is very sensitive to any texture

Please note, this is NOT a quotation, just a confirmation of the price when purchased in the UK exclusive of VAT/duties