Why measure gloss?

Gloss is an aspect of the visual perception of objects that is as important as colour when considering the psychological impact of products on a

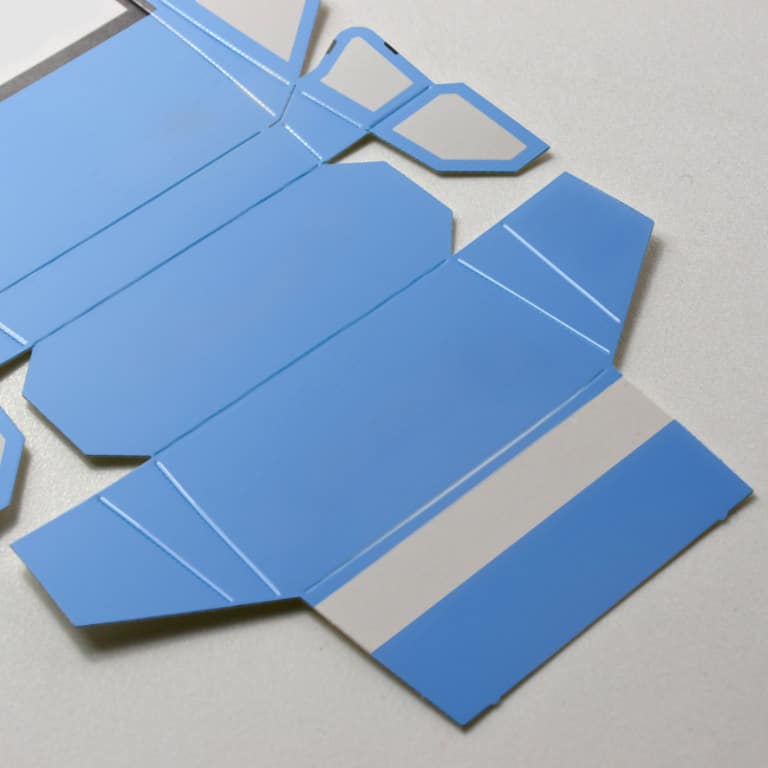

Friction parameters help the manufacturer understand how the finish of the blown film or printed carton can influence the feeding and running speeds. Surface

slip is a key factor when printing, erecting or filling packaging materials on an automatic line.

A product’s slip resistance is characterised by it’s coefficients of friction (COF):

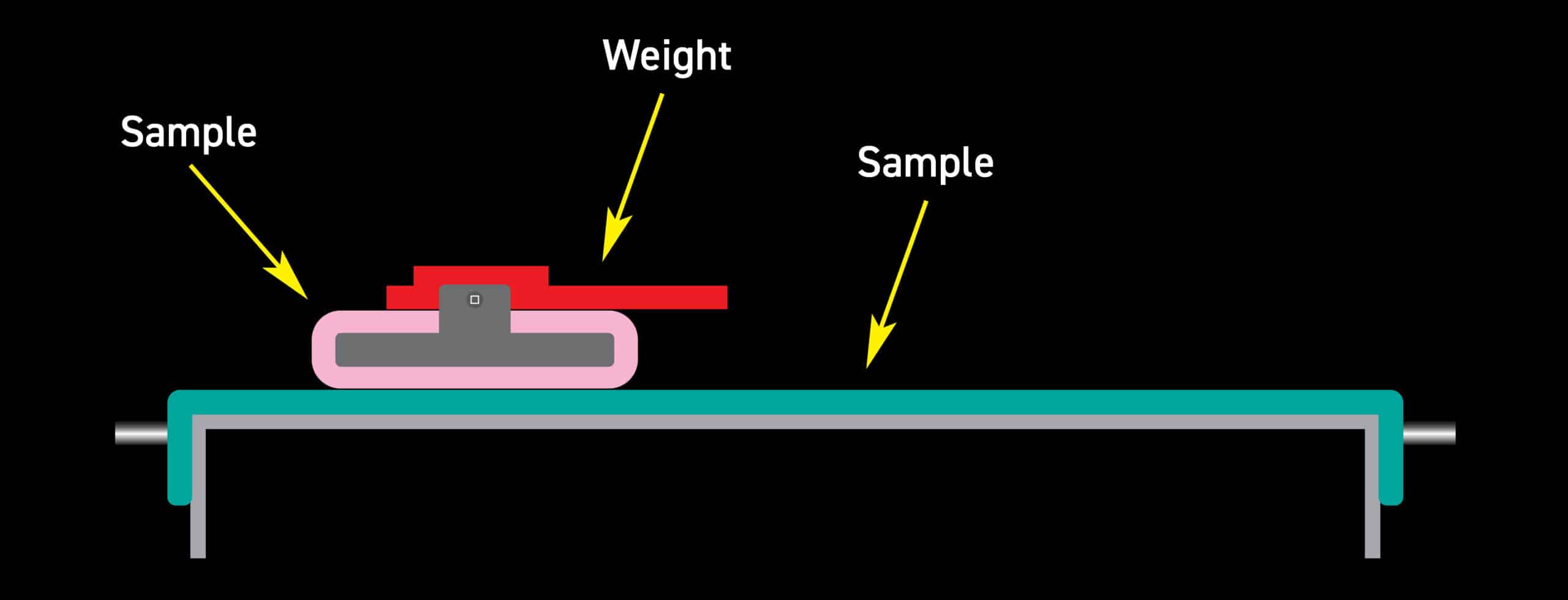

Static COF = Fs/N

Dynamic COF = Fd/N

Where Fs is the maximum static frictional force and the Fd is the average dynamic frictional force. N is the Normal force, i.e. the force of gravity acting on the sample and test sled.

In practical terms, the static slip relates to the force required to get two resting surfaces moving, dynamic slip is the smaller force that is required to keep the surfaces moving once this initial “inertia” is overcome.

These values are expressed as ratios and do not have units, they are usually quoted as a decimal value between 0 and 1.

COF can often be related to the feeding and running attributes of products, for instance UV varnished food cartons have a slip coefficient that is related to the formulation of the UV coating its cure and film weight.

Cartons that have a very low static coefficient of friction may have handling difficulties as they will tend to slide apart and are difficult to place into feeding hoppers.

In contrast, products which have a high COF will tend to stick together and can be prone to misfeeding due to multiple cartons entering the packaging line at once.

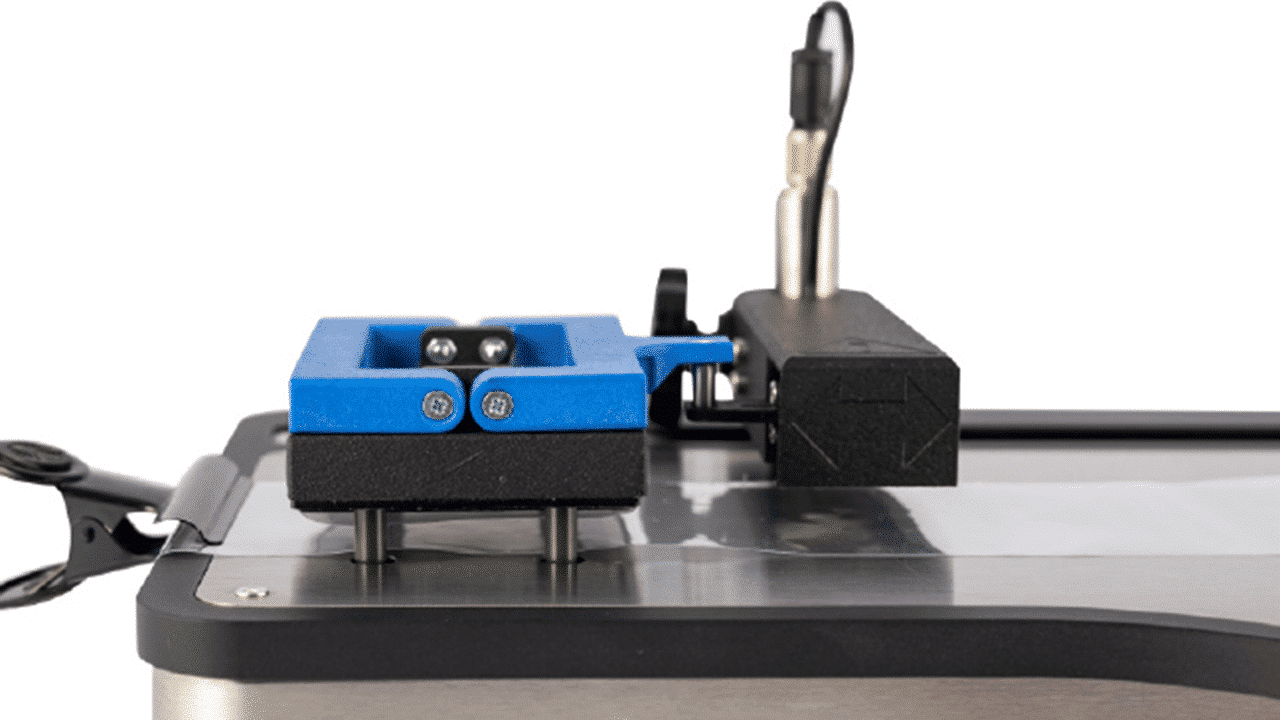

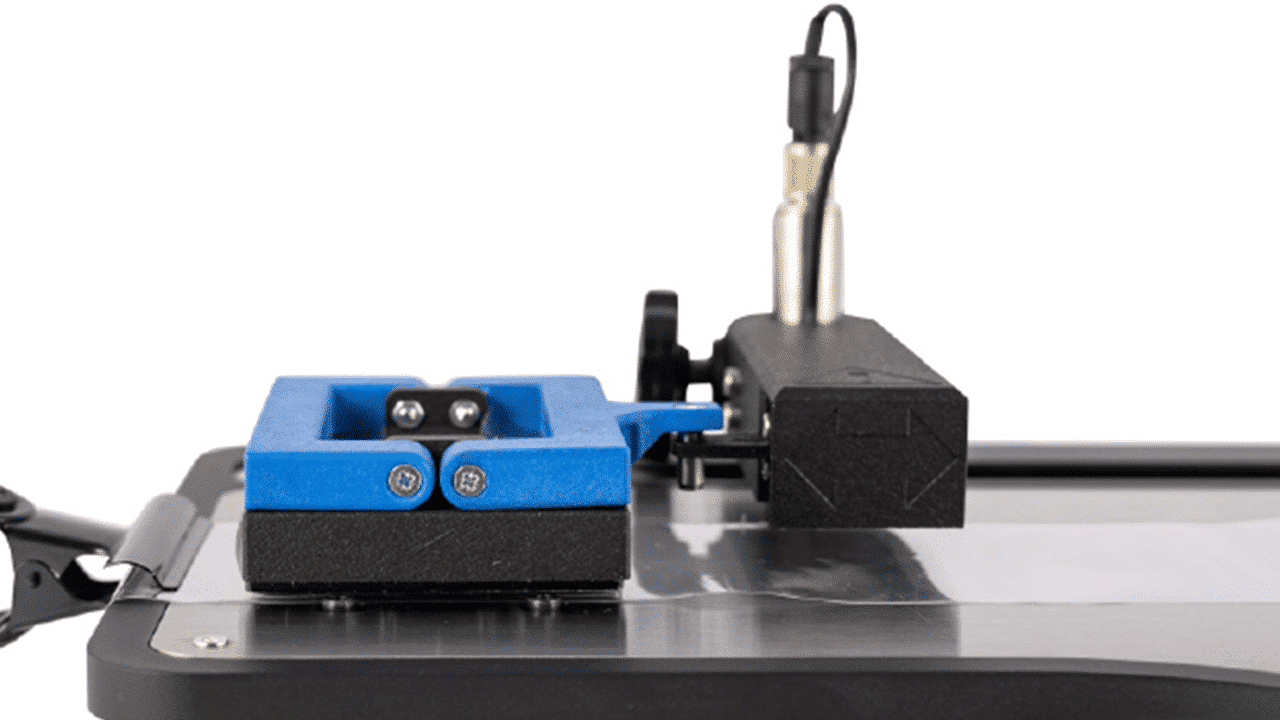

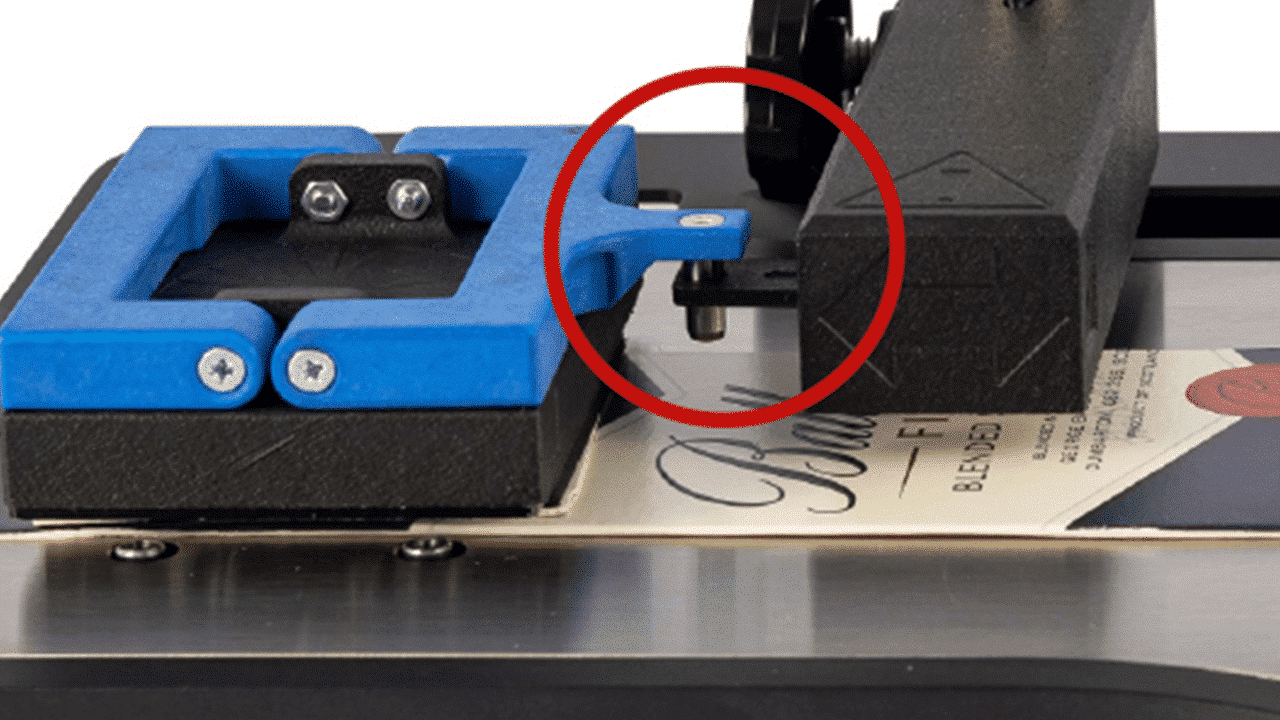

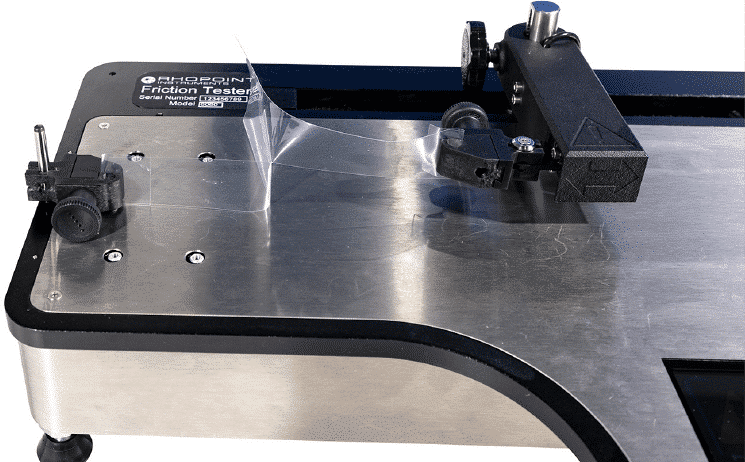

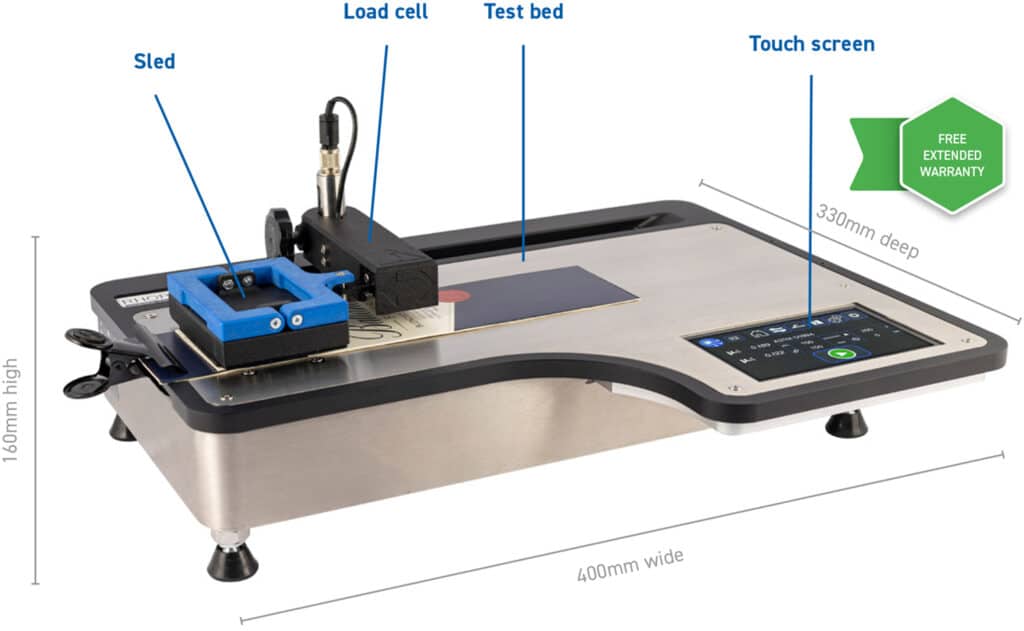

The Universal friction tester allows the user to test static and dynamic coefficient of friction with minimal training. Ultra-repeatable static COF; automatic sled placement with variable dwell times.

A fixed link between the sled and the load cell means that there are no errors in friction from pulley wheels or cords associated with other measuring instruments.

The UFT uses an intuitive touch screen user interface making it accessible and easy to use.

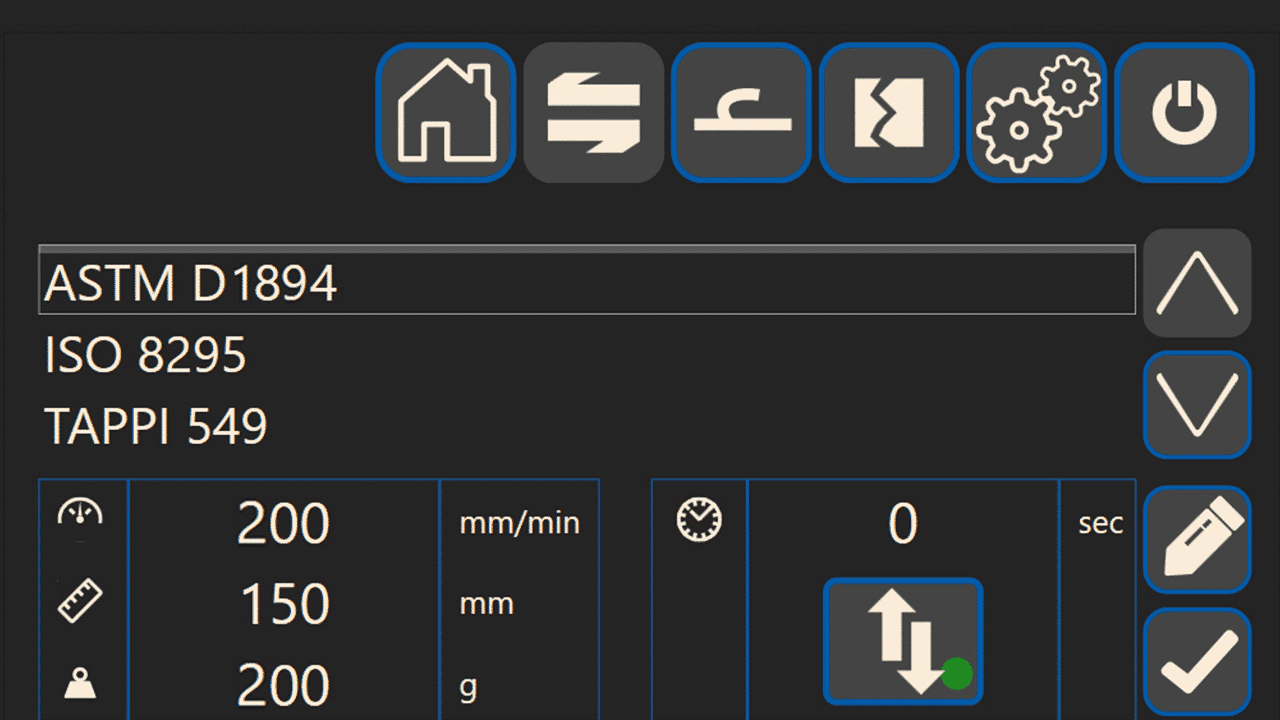

Pre-loaded ISO/ASTM/friction test methods with the option to create a custom test.

The UFT sled design makes the loading of film samples ultra-easy

This standalone instrument is designed for simple QA testing of static and dynamic COF. The instrument is preloaded with ISO/ASTM/friction test methods with the option to create a custom test. Included in the package are the attachments for performing peel, tear and seal strength tests.

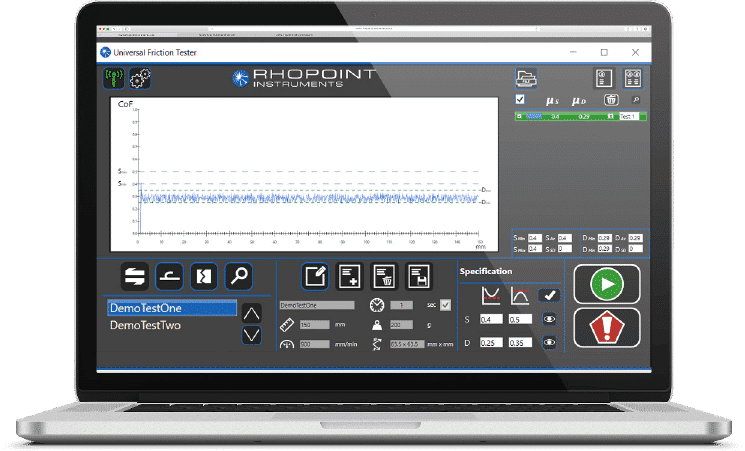

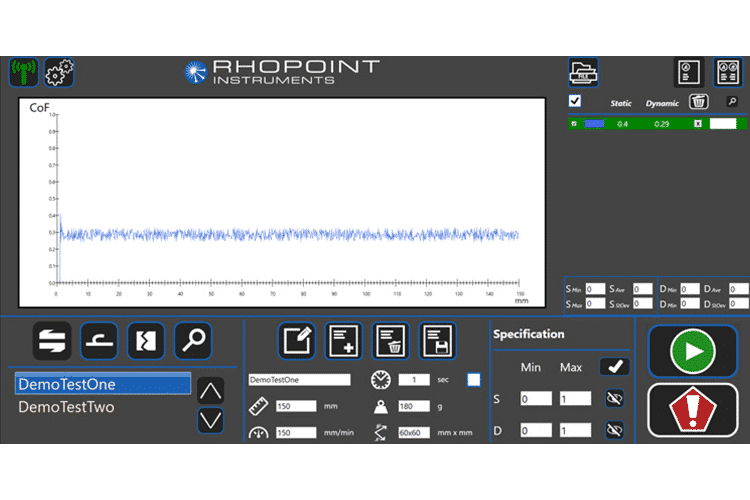

Optional full analysis software allows for detailed statistical and graphical analysis of results, full PDF reporting and the creation of custom test routines.

Included attachments transform the UFT into a precision peel test instrument, accurately measuring the force required to separate glued or laminated films, tapes, labels etc.

Included tear strength attachment allows the user to measure and control tear strength to international standards.

Included test attachments for testing seal integrity of films or laminates.

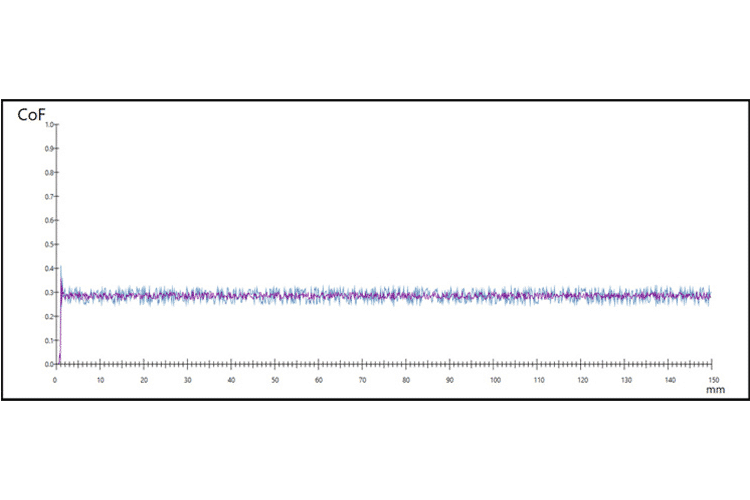

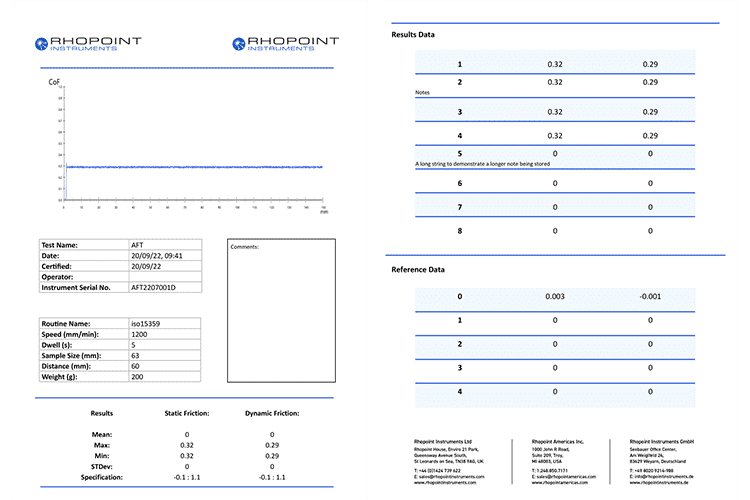

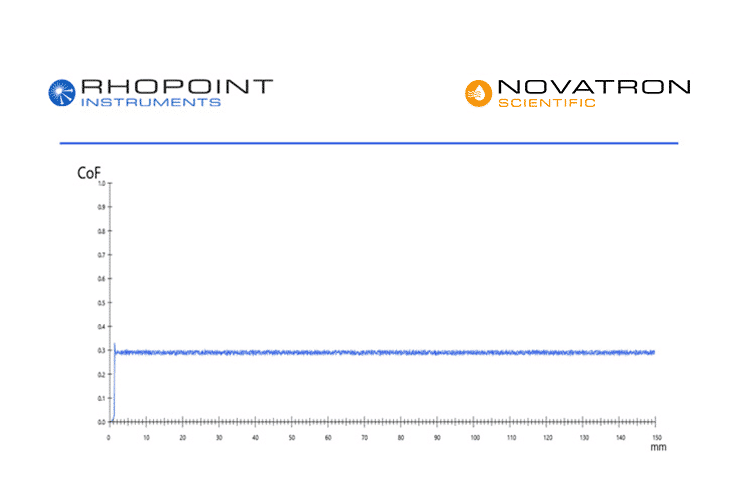

The Universal Friction Tester software features graphical reporting of results and allows unlimited custom test routines to be created in minutes. Tolerances for both static and dynamic COF can be set for each test routine allowing for easy identification of non-conformances.

Multiple tests can be run per file and a graphical trace given for each. A master or reference file for the material

can be overlaid to give a quick visual comparison of batch to batch consistency and quality.

Full graphical and statistical analysis of test results can be printed to PDF for easy reporting.

The logo at the top of the report can be customised to reflect customer own branding.

| Order Code | Description | Size | |

|---|---|---|---|

| HAN-B6060-010 | UFT friction template - board | 63.5 x 63.5mm | |

| HAN-B6060-011 | UFT friction template - film | 63.5 x 148mm | |

| HAN-B6060-012 | UFT peel and seal strength template | 25 x 200mm | |

| HAN-B6060-013 | UFT tear template | 50 x 175mm | |

| HAN-B6060-014 | UFT seal strength template 2 | 15 x 200mm | |

| HAN-B6060-015 | UFT seal strength template 3 | 25.4 x 200mm | |

| RL-B80-001 | Universal roller sample cutter (requires a die, select from below options) | ||

| RL-B-CUTTER/FRICTION | Cutter die - friction - for use with carton & board | ||

| RL-B-CUTTER/FRICTION-PLAST | Cutter die - friction - for use with plastics | ||

Simple sample preparation with the Hanatek Universal Sample Cutter (USC) The Hanatek USC has been designed for the simple cutting of samples for the packaging industry. Additional Dies can be configured to cut samples for most test types including: friction, tensile, grammage, O2 permeability, CO2 permeability, WVTR, rub resistance, carton crease, carton stiffness and many more.

| Weight | 6.5 kg |

|---|---|

| Dimensions | 330 × 400 × 160 cm |

| Standard | Application | Details |

|---|---|---|

| ISO 8295 | Plastics - film and sheeting | Determination of the coefficients of friction |

| ASTM D1894 | Plastics - film and sheeting | Standard test method for static and dynamic coefficients of friction |

| TAPPI 549 | Printing paper | Coefficients of static and dynamic friction of uncoated writing and printing paper by use of the horizontal plane method |

| ASTM D2534 | Wax coating | Standard test method for coefficient of dynamic friction for wax coatings |

| ASTM D3330 | Tape | Standard test method for peel adhesion of pressure sensitive tape |

| FTM1FINAT | Peel test | Test method no. 1, Peel adhesion (180°) at 300mm per minute |

| FTM2FINAT | Peel test | Test method no. 2, Peel adhesion (90°) at 300mm per minute |

| FTM3FINAT | Adhesion | Test method no. 3, Low speed release force |

| FTM21FINAT | Adhesion | Test method no. 21, Ink Adhesion - basic |

| ISO 6383 | Textile | Determination of tear resistance -- Part 1: Trouser tear method |

| ASTM F88 | Seal | Standard test method for seal strength of flexible barrier materials |

| Instrument Specification | Details |

|---|---|

| Resolution | 0.1g / 0.001 COF |

| Accuracy | 0.5g |

| Sleds | 200g, Other sled weights by request. Custom sled base materials available |

| Speed | User definable, 100 - 1200mm/min |

| Dwell Time | User definable, 0-90 seconds |

| Test distance | User definable, up to 200mm |

| Power | 110/240v 50/60Hz |

| Load cell capacity | 30N |

| Size | (H) 160mm x (W) 400mm x (D) 330mm |

| Net weight | 6.5kg |

| Gross weight | 10kg |

| Touch Screen PC Information | ||

|---|---|---|

| HAN-A6060FRICTION | Universal Friction Tester Includes peel, tear and seal test attachments | |

| HAN-B6060-001 | UFT Lab software package, includes USB-Network adapter and network cable | |

Free extended 2 year warranty: Requires registration at www.rhopointinstruments.com/help-services/forms-feedback/instrument-registration/ within 28 days of purchase. Without registration, 1 year standard warranty applies.

Fast and economic service via our global network of accredited calibration and service centres. Please visit www.rhopointinstruments.com/help-services/calibration-servicing/ for detailed information.

Gloss is an aspect of the visual perception of objects that is as important as colour when considering the psychological impact of products on a

Identify the surface that you wish to measure. Is it a flat surface? If so, it can be measured with a traditonal glossmeter. Curved surfaces

RSpec is the peak reflectance measured over a very narrow angular band in the specular direction (+/-) 0.0991º. RSpec is very sensitive to any texture

Please note, this is NOT a quotation, just a confirmation of the price when purchased in the UK exclusive of VAT/duties

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.