Table of Contents

Related FAQs

FAQ Categories

What is orange peel?

When a person hears the term “orange peel” they instantly think of the outer skin of an orange and the textured appearance it has; to a coatings specialist however these words can mean a major headache in terms of how they are going to control the surface appearance of their coatings.

For many years in the coatings industry, orange peel has been used as a term to describe the visual sensation of texture on a painted surface. This texture is a combination of different structure sizes that can be caused by a number of different variable in the surface preparation and painting process.

In some industries such as the decorative paint industry, orange peel is desirable as it can create an attractive patterned surface for walls. However in the automotive industry, specific actions are taken to reduce the orange peel effect to a minimum in order to give a sharp, high contrast “quality” visual sensation, so that when the car in the showroom is viewed by a potential customer they get that “wow” feeling which eventually leads them to purchasing.

Factors that influence the levels of orange peel during manufacture can be classified into specific process areas. For example, during substrate material preparation, the use of incorrect abrasive materials can create fine structures on the material surface which can cause problems later down the line during paint application. Variations in the coating itself, i.e. coating thickness, viscosity and flow characteristics, particle size distribution and raw material quality can create larger structure sizes in the finished surface; also the orientation in which the coating is applied will cause more or less orange peel to be created, vertical application will always be greater than horizontal.

So from a coatings specialist point of view, the control of all these factors is critical in maintaining consistency of surface appearance quality of the finished product.

The Rhopoint IQ can detect changes in the orange peel of high gloss finishes. This instrument is used to measure orange peel in the paint industry.

Related products

Concrete Clarity Meter (CCM)

- Industry standard Concrete Clarity Meter

- Measures Gloss, Haze and DOI of polished concrete

- 20/60˚ Glossmeter for high gloss finishes

- Compatible with concrete polishing standards

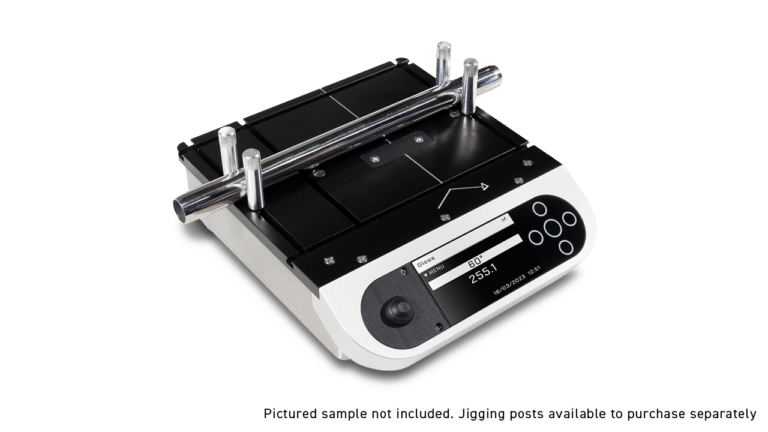

Novo-Curve 4 Glossmeter

- Benchtop glossmeter, Measures at 60°

- Suitable for both curved & flat surfaces

- Precise measurement of small areas & irregular shapes

- Custom adaptor jigs available

- To ensure accurate and reliable results, the Novo-Curve 4 Glossmeter is supplied with standards calibrated and certified according to ISO 17025 UKAS

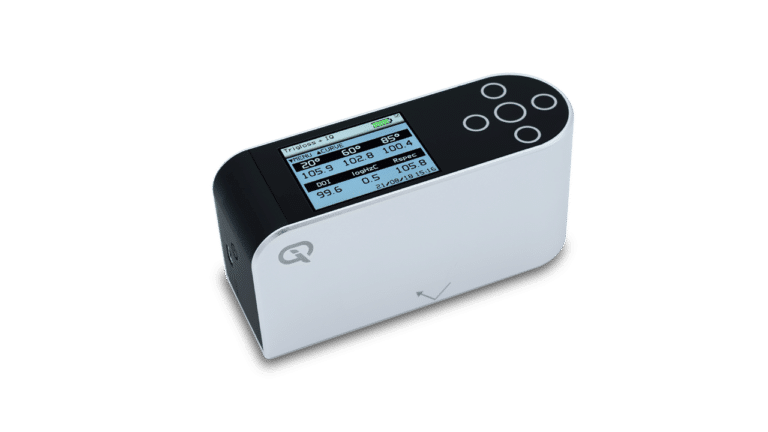

Novo-Gloss 20/60/85 Glossmeter with Haze to ASTM E430

- 20/60/85° gloss meter for matt to mirror finishes

- Haze measurement to ASTM E430

- Full statistical analysis with trend graphs

- Does the surface to be measuring have texturing?

Novo-Gloss 45 Glossmeter

- 45° glossmeter for all gloss applications

- Specialist angle for the measurement of films and ceramics

- Full colour easy to read screen

- Easy reporting