Appearance & Measurement Experts since 1986

A combination of perception metrics that comprehensively describe the reflectivity and visual quality of high-quality, high-gloss surfaces.

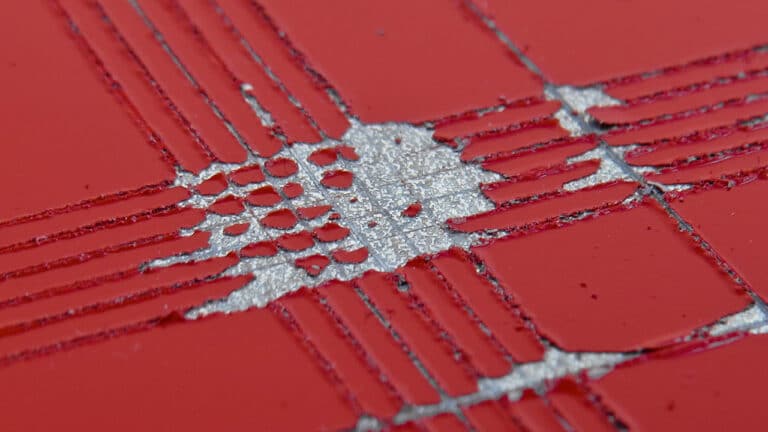

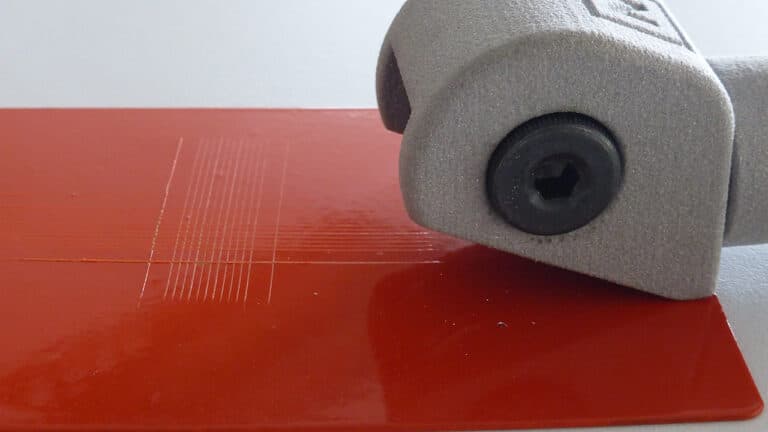

Aesthetix Cross-cut Adhesion Module replaces the subjective analysis of reproducible imaging measurement, increasing the speed and accuracy of a critical test which quantities durability and performance of a coating under various conditions.

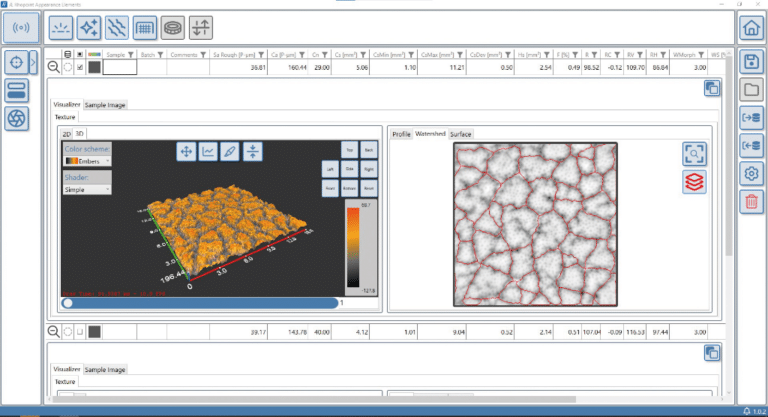

Coatings with effect pigments exhibit sparkle and coarseness. Sparkle refers to a visual texture observed when mirror-like elements within a surface reflects light.

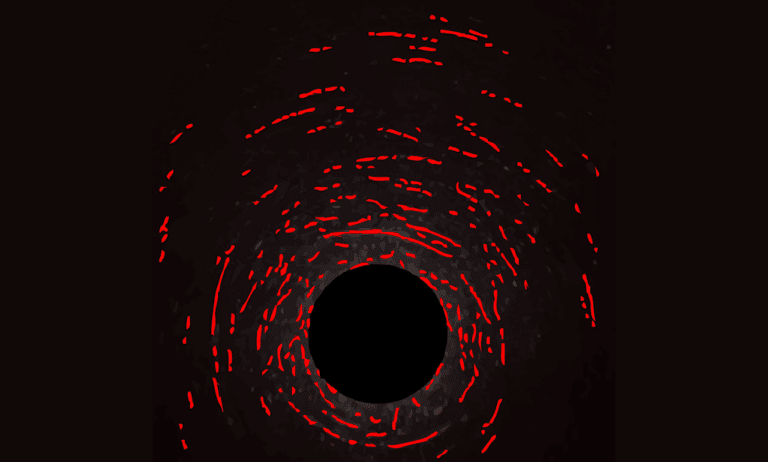

The Rhopoint Polishing Quality Module is designed to objectively quantify scratches, holograms, and swirls on high-gloss automotive surfaces.

The Rhopoint Aesthetix® analyses surface texture to help manufacturers create consistent products with optimum visual appearance and tactile qualities.

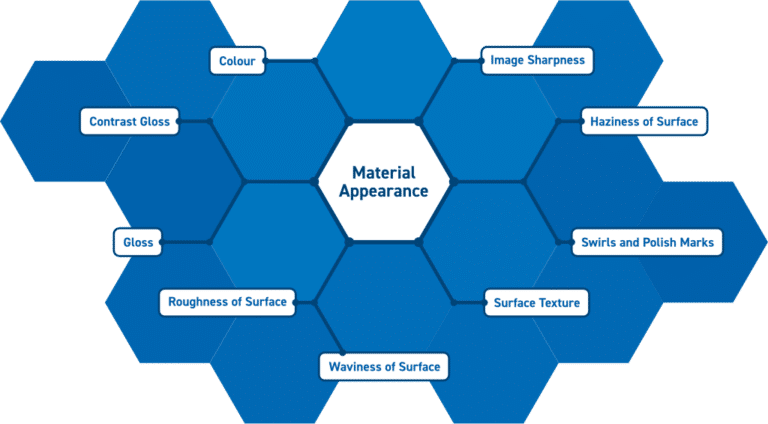

Multiple aspects of surface appearance contribute to how the quality of a surface is perceived. Consumers subconsciously observe the glossiness, colour, translucency and texture of surfaces when judging the aesthetic appeal of a product.

Product aesthetics is a major factor in driving consumer purchase. Designers and manufacturers invest significant resources in optimizing materials and processes for maximum consumer appeal.

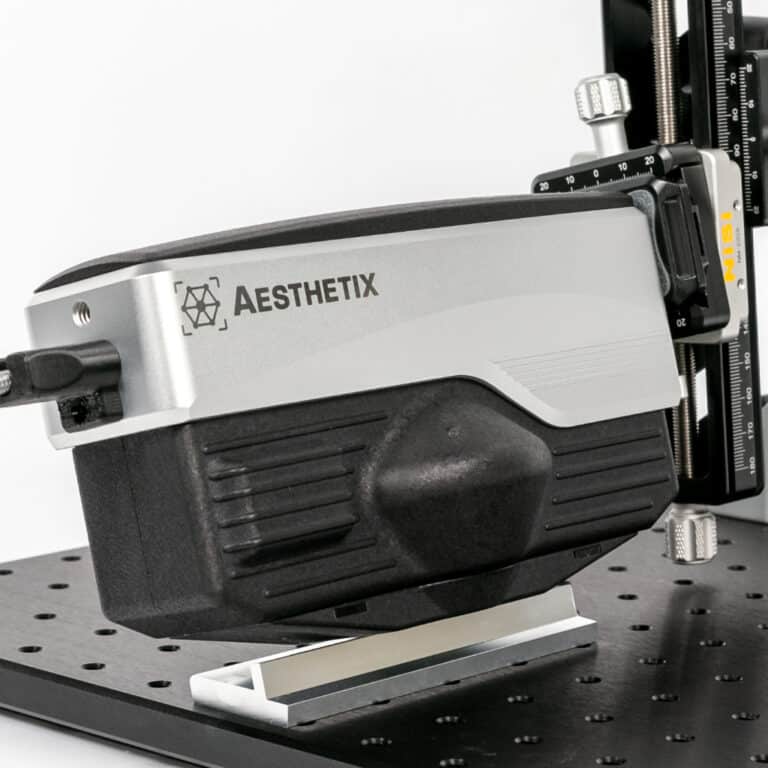

Aesthetix® uses cutting-edge measurement technology* to quantify overall surface appearance with the closest correlation to human perception.

*Measurement technology co-developed with industrial and academic partners.

Aesthetix® is an advanced system that predicts the impact of surface quality on consumer perception using new measurement metrics.

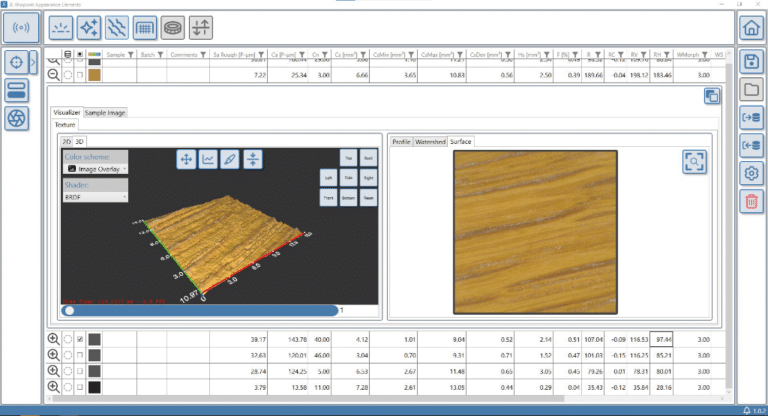

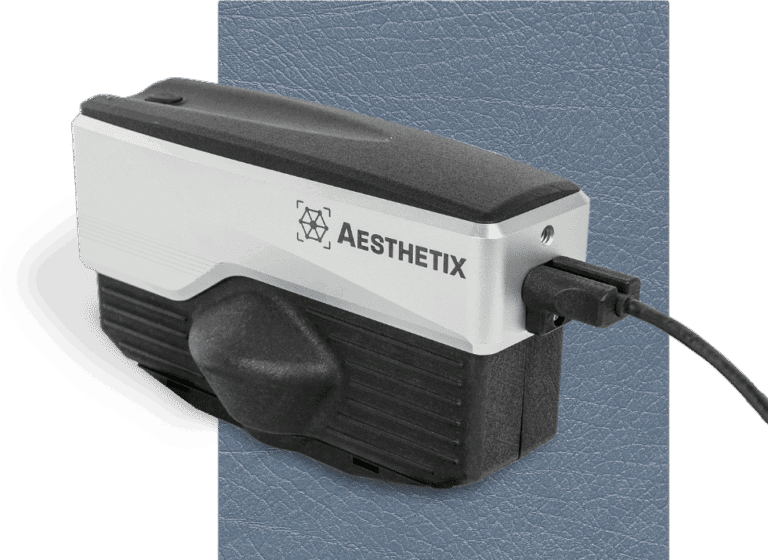

This modular device measures all aspects of surface quality, including glossiness, texture, topography, surface patterns, and visual homogeneity. Adaptable to various workflows, it can measure flat, curved, and small areas with contact or non-contact methods. Aesthetix® can distill complex measurement into easy to understand perception parameters which can be used to set pass/fail tolerances. Enhanced with Rhopoint Appearance Elements software, it supports data sharing, storage, analysis and reporting, making it a comprehensive tool for surface quality assessment.

Use Aesthetix® perception metrics to understand what makes a perfect surface finish in the eyes of the consumer. Set new standards with defined pass/fail criteria.

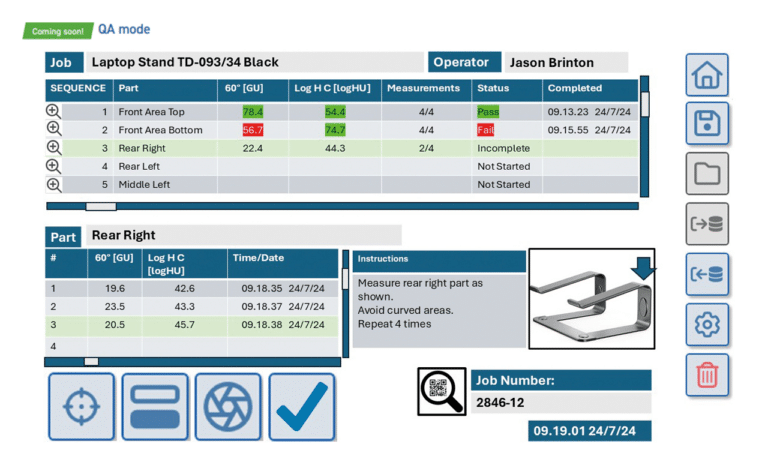

A simple QA interface with job based work flow can be employed for routine surface inspection.

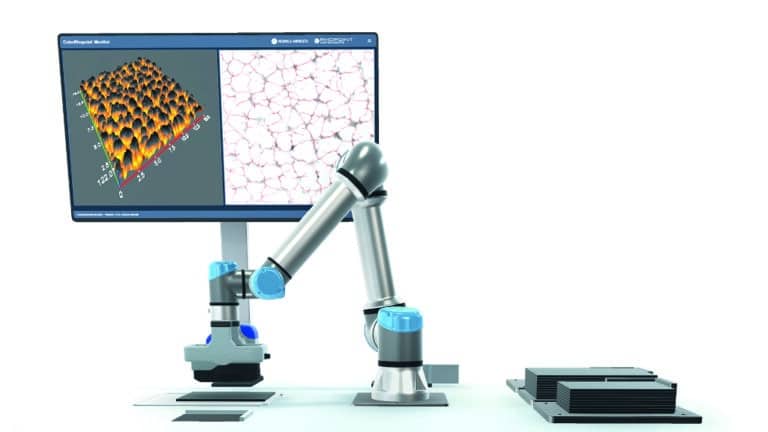

Designed for automation, the noncontact Aesthetix® sensor can be integrated into a cobot or robot measurement cell.

Connected to a tablet, the Aesthetix® can be used as a portable off-site measurement tool.

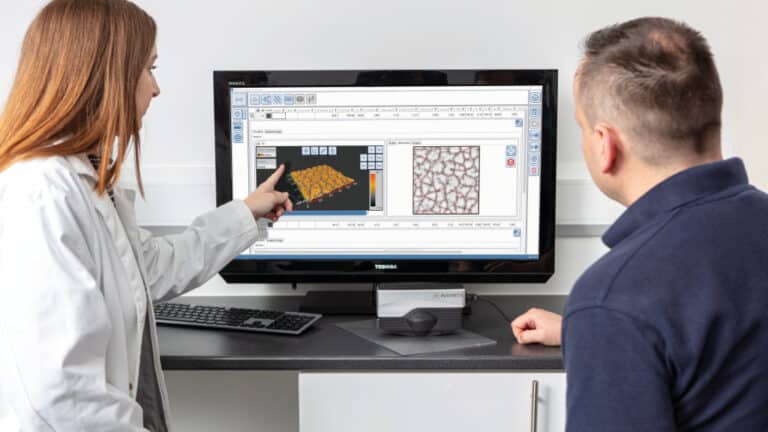

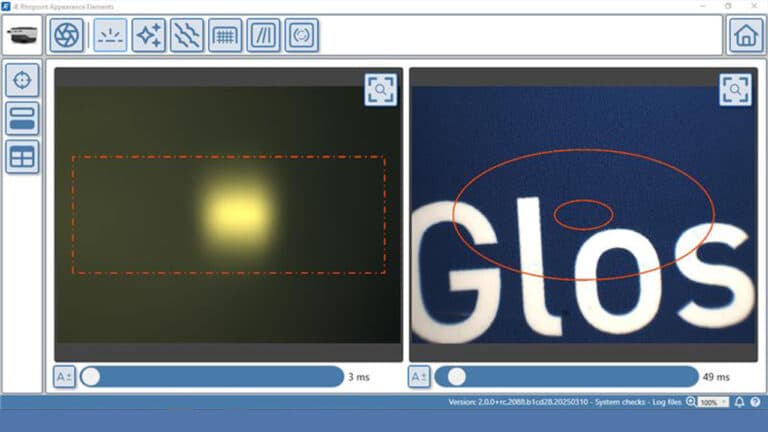

Rhopoint Appearance Elements software is used to analyse measured results by comparing values, images and topographical information against reference standards.

Rhopoint Appearance Elements provides a structured, fully indexed database for precise process optimisation and future AI-driven decision-making.

A local database stores results, data and images from a single instrument. Data and images can be output for further analysis.

A network database for multiple instruments and locations.

Host your database on the Rhopoint cloud or use your organisation’s cloud.

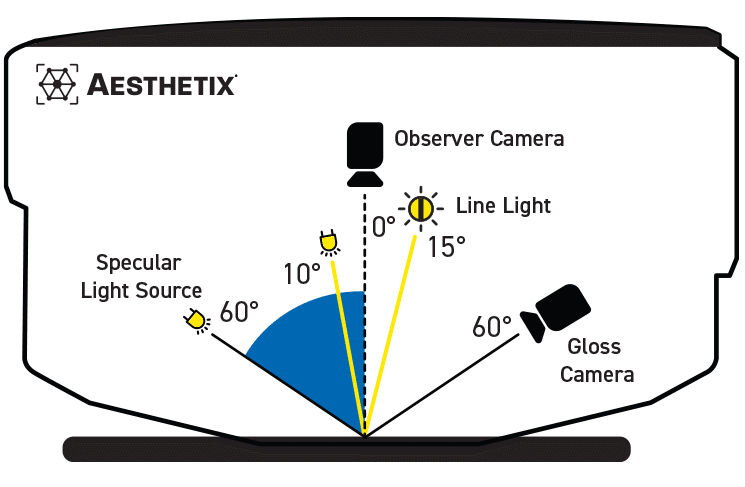

Dual camera system:

Designed to capture detailed information about the surface and how it interacts with light.

Observer camera:

Captures a highly detailed colour-correct image of the surface.

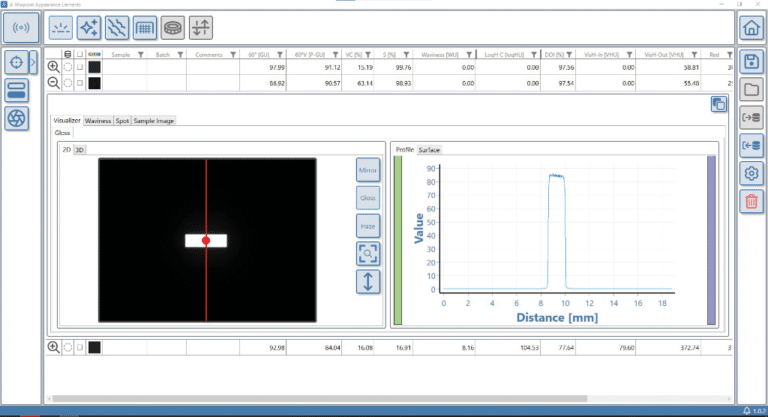

Gloss camera:

HDR images are used to characterise multiple aspects of surface glossiness.

Specular light source:

Conforming to ISO 2813 and ASTM D523, this is used in the calculations for gloss, visual gloss, DOI, sharpness, haze, visual haze.

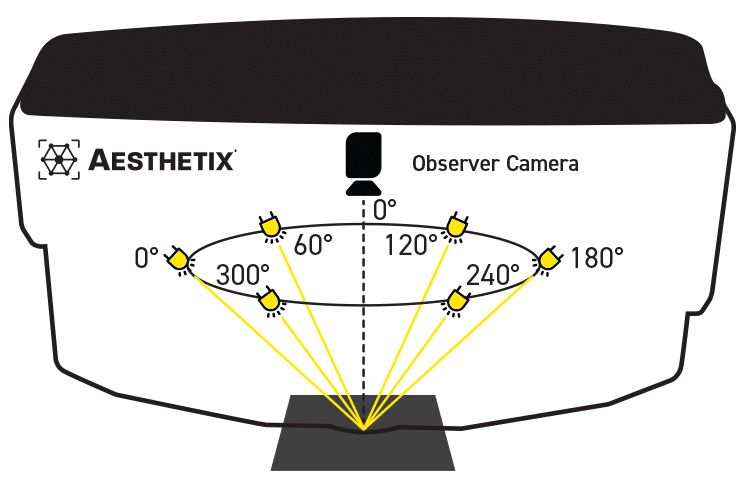

6 x 45° ring lights:

Used to light the surface for image capture, sparkle analysis and photometric stereo.

Line light:

Used to measure orange peel and surface waviness.

10° spot light:

Used in the analysis of scratches, holograms and haze.

The Aesthetix® instrument vision system comprises of a sensor unit connected via USB 3.0 supporting onsite inspection with a tablet, surface analysis with a laboratory PC and in-line quality control via SPC.

This modular device measures all aspects of surface quality, including glossiness, texture, topography, surface patterns, and visual homogeneity. Adaptable to various workflows, it can measure flat, curved, and small areas with contact or non-contact methods.

Interchangeable measurement adaptors allow for measurement of flat surfaces, small parts, small areas and curved surfaces.

The instrument is able to accept custom jigs and adaptors for more repeatable measurement of small and complex parts.

For non-contact measurement of delicate surfaces, liquid coatings, gels, creams and pastes, Aesthetix® can be used with a height-adjustable stand.

High-throughput sample analysis can be achieved with Aesthetix® integrated into a laboratory cobot system.

The Aesthetix® can be integrated into a production environment as a non-contact in-line sensor.

Rhopoint Appearance Elements software is at the heart of the Aesthetix® instrument vision system, capturing images for analysis with cutting-edge algorithms. Measurement images, graphs, and topographical surface maps illustrate the appearance qualities of the surface. Numeric results and images are stored in a local, network or cloud database, ensuring secure, scalable data management.

Create the perfect surface finish by measuring all the parameters that affect visual appearance and match what your eye sees.

A dual camera sensor with innovative lighting captures HDR surface and gloss images with exceptional resolution lower than the human eye.

The Rhopoint Appearance Element software uses perception algorithms to calculate parameters that predict the human visual response to important surface characteristics.

Uniquely, the Rhopoint Appearance Element software allows technical control based on ISO or ASTM standard procedures and at the same time, checks for visual judgment.

A combination of perception metrics that comprehensively describe the reflectivity and visual quality of high-quality, high-gloss surfaces.

Aesthetix Cross-cut Adhesion Module replaces the subjective analysis of reproducible imaging measurement, increasing the speed and accuracy of a critical test which quantities durability and performance of a coating under various conditions.

Coatings with effect pigments exhibit sparkle and coarseness. Sparkle refers to a visual texture observed when mirror-like elements within a surface reflects light.

The Rhopoint Polishing Quality Module is designed to objectively quantify scratches, holograms, and swirls on high-gloss automotive surfaces. Additionally quantifying gloss, haze, sharpness / DOI for a complete surface characterisation. Ideally suited for manufacturers optimising polishing processes and evaluating spot repairs.

Materials with surface texture such as automotive interior plastics, leather and powder coatings need to have uniformity of appearance and pattern to have maximum visual appeal. The Rhopoint Aesthetix® analyses surface texture to help manufacturers create consistent products with optimum visual appearance and tactile qualities.

Aesthetix is powered by Rhopoint Appearance Elements Software

We offer two options for you to try out the Aesthetix® before buying.

Online demonstration: Online presentation of the Aesthetix® with your samples measured LIVE on Microsoft Teams. Includes a consultation with an application specialist.

Factory sample testing: Send in samples of your material for testing and receive a comprehensive test report.

Please note, this is NOT a quotation, just a confirmation of the price when purchased in the UK exclusive of VAT/duties