Appearance & Measurement Experts since 1986

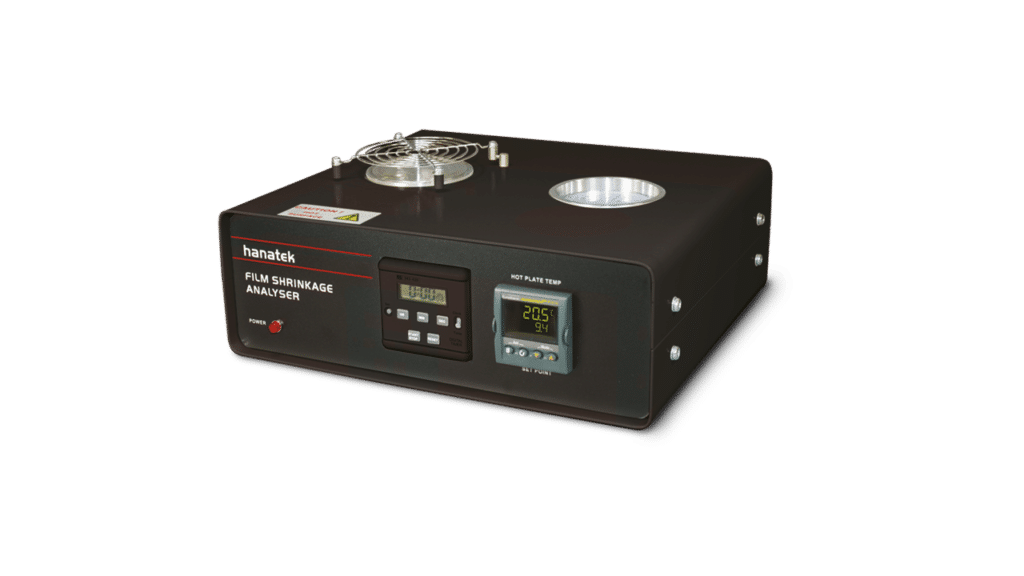

The Hanatek Film Shrink Tester (FST) has been designed to quickly and easily measure the

effect of temperature on plastic film.

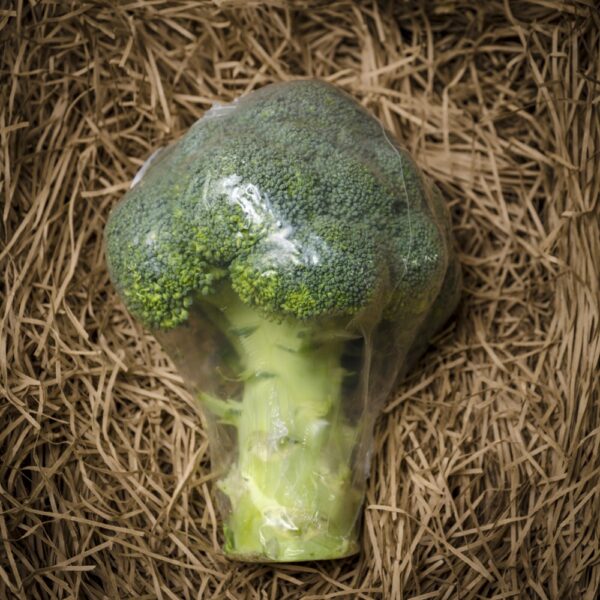

The application of heat causes certain plastic films to rapidly contract; this effect can be used to seal and pack many items from food to consumer goods.

The shrink effect is due to internal forces locked into the film during manufacture being released by heating, it is also known as linear thermal shrink or free shrink. The amount of shrinkage is dependent on the film type, thickness and sealing temperature.

Testing the percentage shrink of a film ensures that it is suitable for a particular packaging application and establishes the correct temperature for that application.

Film shrinkage is important to industry as blown films are often heat treated to form protective packaging for perishable food or manufactured products.

Blown plastic films contract when heated, this effect is used to seal or protect food or industrial products. In contrast a film that exhibits too much shrinkage may distort a product or form a weak functional barrier.

The Hanatek film shrink tester is used to measure the effect of temperature on blown films.

| Instrument Specifications | ||

|---|---|---|

| Standards | Results equivalent to ASTM D2732 (hot oil bath test method). This is a safer and more cost effective laboratory measure of percentage shrink | |

| Display | LCD with set point and actual temperature reading | |

| Temperature | Range: 40-200°C | |

| Accuracy | Accuracy: ±0.3°C | |

| Timer | Lapse timer with alarm registers overshoot | |

| Dimensions | 120mm (H) x 300mm (W) x 270mm (D) | |

| Weight | 4.7kg | |

| Packed Weight | 6.1kg | |

| Packed Dimensions | 350mm (H) x 450mm (W) x 290mm (D) | |

| Commodity Code | 9027 8017 | |

Free extended 2 year warranty: Requires registration at www.rhopointinstruments.com/help-services/forms-feedback/instrument-registration/ within 28 days of purchase. Without registration, 1 year standard warranty applies.

Fast and economic service via our global network of accredited calibration and service centres. Please visit www.rhopointinstruments.com/help-services/calibration-servicing/ for detailed information.

Selecting the correct angle for the application will optimise measurement accuracy. Three types of instruments are available on the market: 60° single angle instruments, a

The diagram above shows the same coating applied to two panels, the first has orange peel/waviness present due to the incorrect application setting on the

Please note, this is NOT a quotation, just a confirmation of the price when purchased in the UK exclusive of VAT/duties