Appearance & Measurement Experts since 1986

Identify the surface that you wish to measure. Is it a flat surface? If so, it can be measured with a traditional glossmeter.

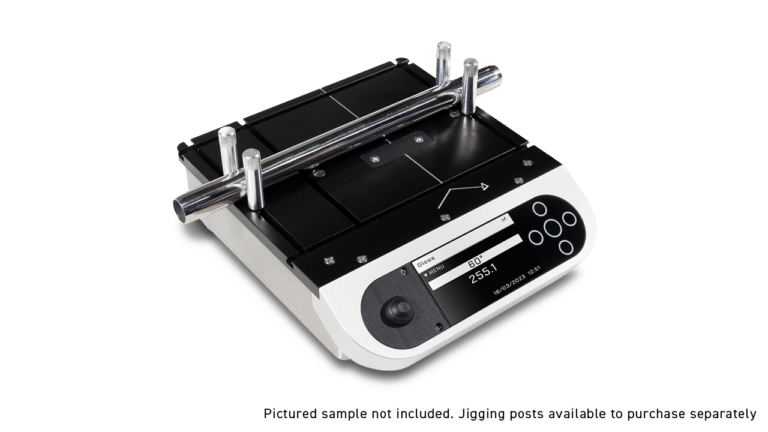

Curved surfaces should be measured using equipment specifically designed for this type of application. Benchtop and handheld instruments are available for these applications.

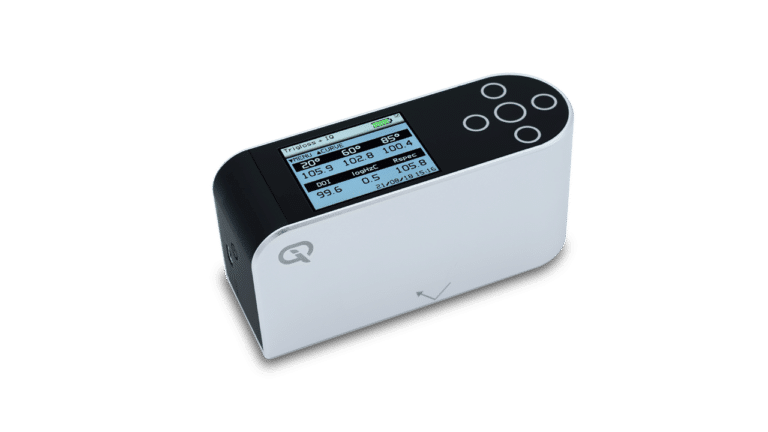

Selecting the correct glossmeter is dependent on the application and level of gloss of the surface. Each gloss meter specifies the measuring angles utilised.

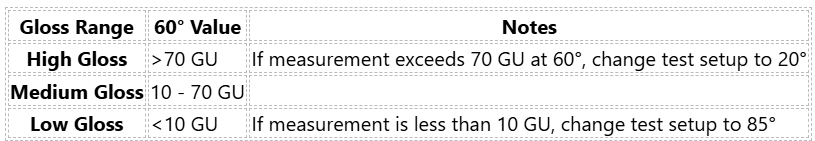

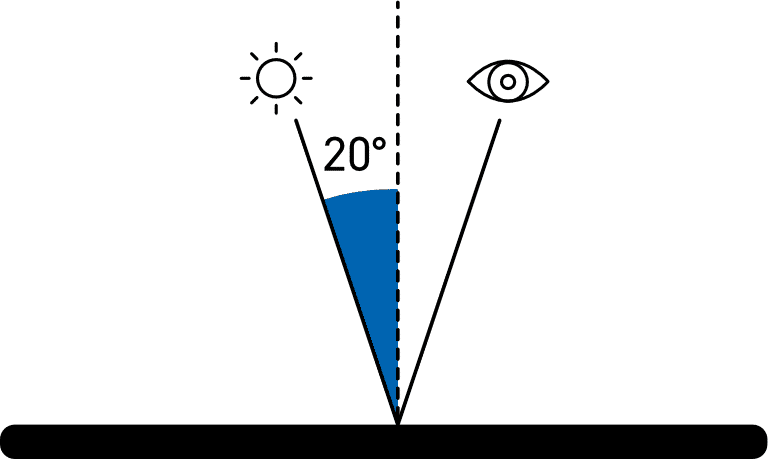

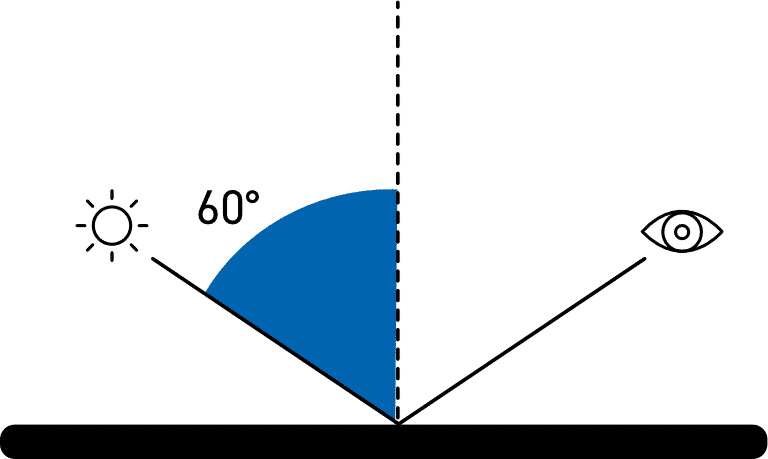

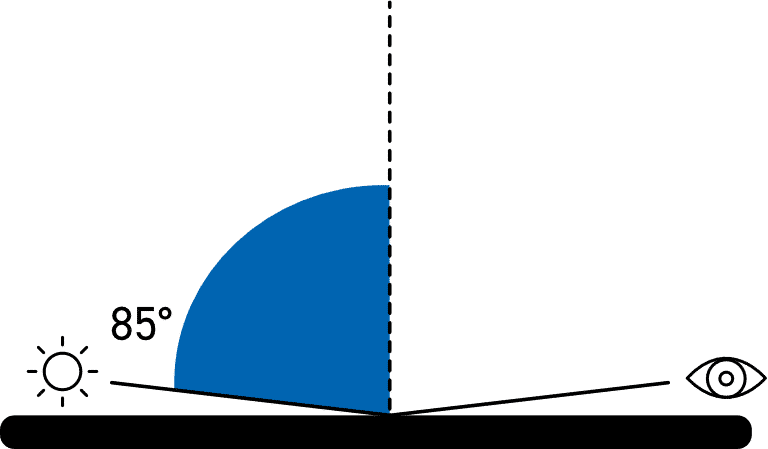

‘Measurement angle’ refers to the angle between the incident and reflected light. Three measurement angles (20°, 60°, and 85°) are specified to cover the majority of coatings applications. The angle is selected based on the anticipated gloss range, as shown in the following table:

Selecting the correct angle for the application will optimise measurement accuracy.

Three types of instruments are available on the market: 60° single angle instruments, a combination of 20° and 60° and one type that combines 20°, 60° and 85°.

Two additional angles are used for other materials. An angle of 45° is specified for the measurement of ceramics, films, textiles and anodised aluminium, whilst 75° is specified for paper.

If a the appearance of a high gloss surface is affected by surface texture such as orange peel or a ‘milky’ finish or halos around reflections of bright light, these will need to be measured with the Rhopoint IQ