Appearance & Measurement Experts since 1986

Thickness directly affects a product’s functionality, quality, and cost. It influences key performance properties such as tensile strength, rigidity, barrier performance, puncture resistance, and opacity.

Consistent thickness also maintains product quality and the expected tactile feel, while poor accuracy can lead to customer rejections and costly rework.

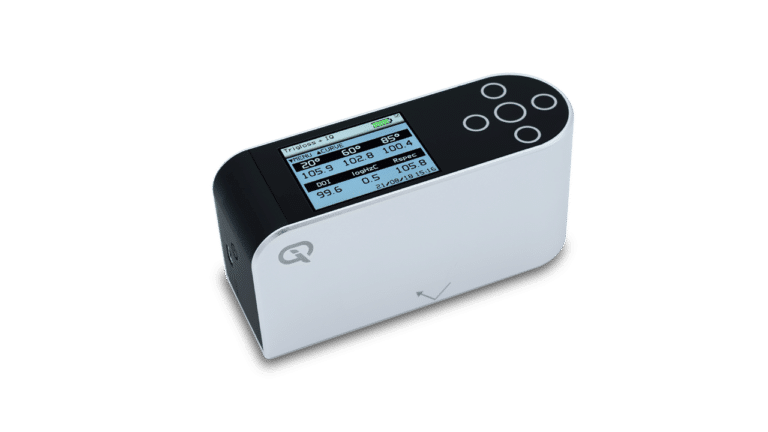

The FT3 thickness gauge helps manufacturers stay within tight tolerances, improve consistency, reduce raw material use, and provide traceable, time-stamped records that prove compliance throughout production.

Thickness is a key parameter for many manufacturers as it affects the functionality, quality and cost of finished products.

The FT3 thickness gauge allows product to be manufactured within tight tolerances targeted right in the middle of a customer’s specification.